Custom Programming for Market Needs

Customization also plays a vital role in meeting market-specific needs. It is often necessary to meet the specific needs of different markets, but it is a complex and resource intensive process. Companies face the challenge of developing custom programming while managing tight timelines and limited resources. This involves not only creating a custom SOM part number, but also making sure that the programming aligns with the company’s security standards.

To address this challenge, companies need a streamlined process for custom programming that eliminates the need for initial programming at their production facilities. This can save significant time and reduce costs, allowing teams to focus on other aspects of their product development. Ezurio’s Support+ provides customers with a custom part number programmed with whatever software image they specify, eliminating this laborious process. This service can also be combined with our Summit Suite Chain of Trust Device Security service to manage and secure device keys and certificates.

Use Case Example

Let’s bring up a customer use case that was supported by Support+. This company was developing a factory equipment monitoring device for real-time diagnostics, designed to monitor the health of machinery, such as motors and pumps, by collecting data on vibrations, temperature, and other variables. However, the engineering team faced several critical issues:

- Interference: the factory environment was filled with electromagnetic interference from heavy machinery, which disrupted data transmission.

- Antenna Design: the team lacked RF expertise, resulting in poor antenna placement and connectivity issues.

- Customization: they needed custom programming to collect and process data from multiple sensors while following industry-specific security protocols.

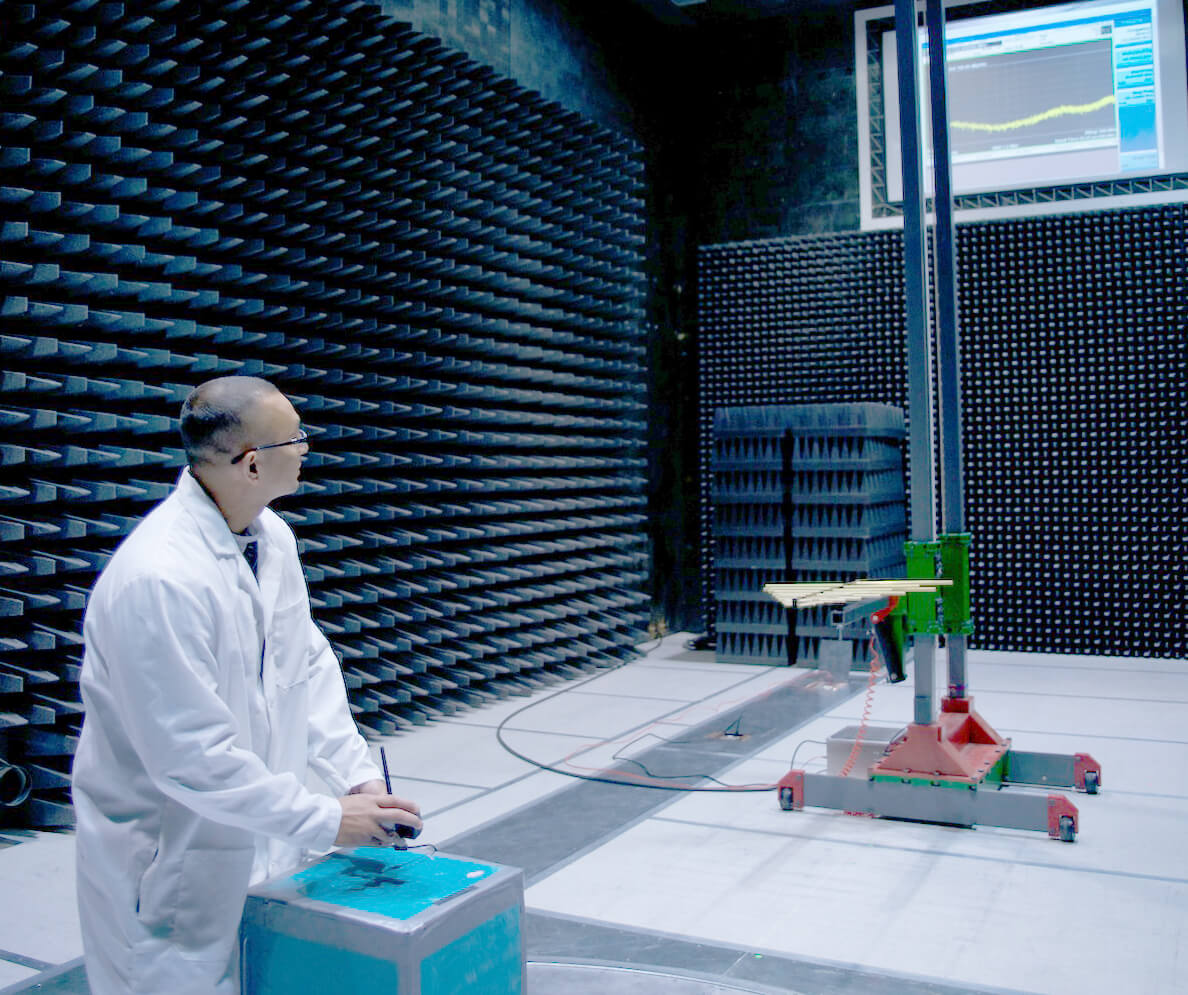

Ezurio helped solved these pain points through the SOM Support+ package. To resolve the connectivity issues, Ezurio’s RF engineering conducted EMC testing to understand the specific requirements, developed tailored test plans, and troubleshooted issues at their antenna chambers in Cedarburg, Wisconsin. Alongside the antenna support, our FAEs identified and resolved several design flaws in their PCB before they could cause delays, streamlining the development process with full-service support.

Ezurio also provided a comprehensive custom programming solution. This involved integrating sensor data from multiple sources into a cohesive real-time monitoring system. Custom SOM part numbers were created, loaded with software images specifically tailored to the company’s needs.

By leveraging Ezurio’s Support+ package, the company successfully overcame the challenges in developing their factory equipment monitoring device. Ezurio not only addressed the immediate connectivity and design issues, but also ensured a long-term reliability and security solution through their custom programming.

With Ezurio’s expert resources and tailored solutions, your engineering team can similarly reduce design risks, optimize performance, and accelerate time to market.

To learn more about Support+, visit: https://www.ezurio.com/system-on-module/support-plus

Laird Connectivity is now Ezurio

Laird Connectivity is now Ezurio