Use Case: Manufacturing Plant

Although wired connections play a crucial role, the importance of wireless connectivity is growing exponentially. Devices and machines, including smart sensors, machine vision cameras, and HMIs, are wirelessly collecting and transferring information across the manufacturing floor. With the latest technology, including Wi-Fi 6 and Bluetooth 5, these wireless standards offer higher data rates, increased capacity, improved power efficiency, and better performance.

Devices communicate in real-time, optimizing operations and reducing downtime. Even for emerging technologies, such as AI, machine learning, and collaborative robotics, rely heavily on wireless. The result is a smarter, more connected factory that can anticipate maintenance needs and adapt to new production demands.

Key Ezurio Benefits:

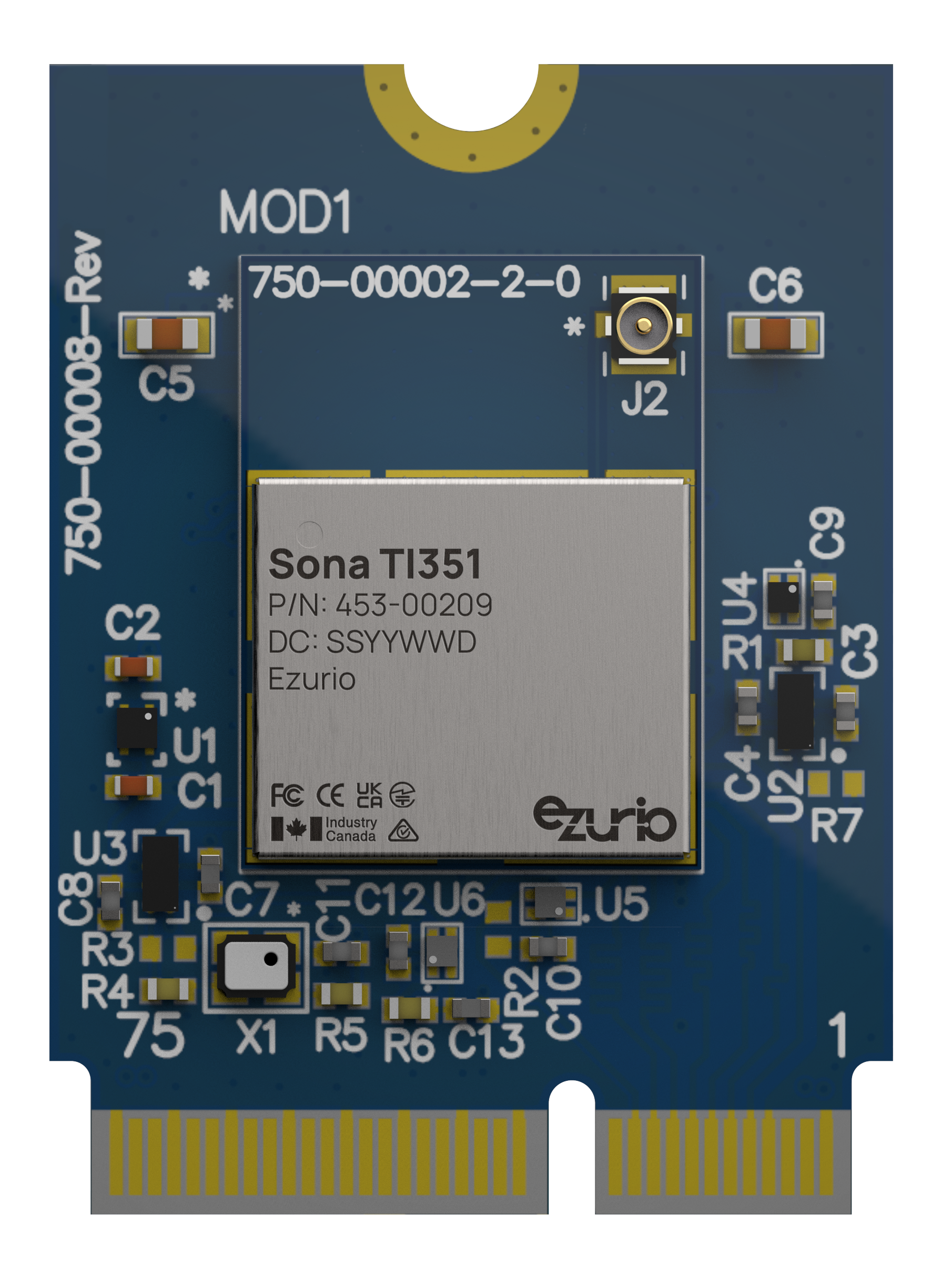

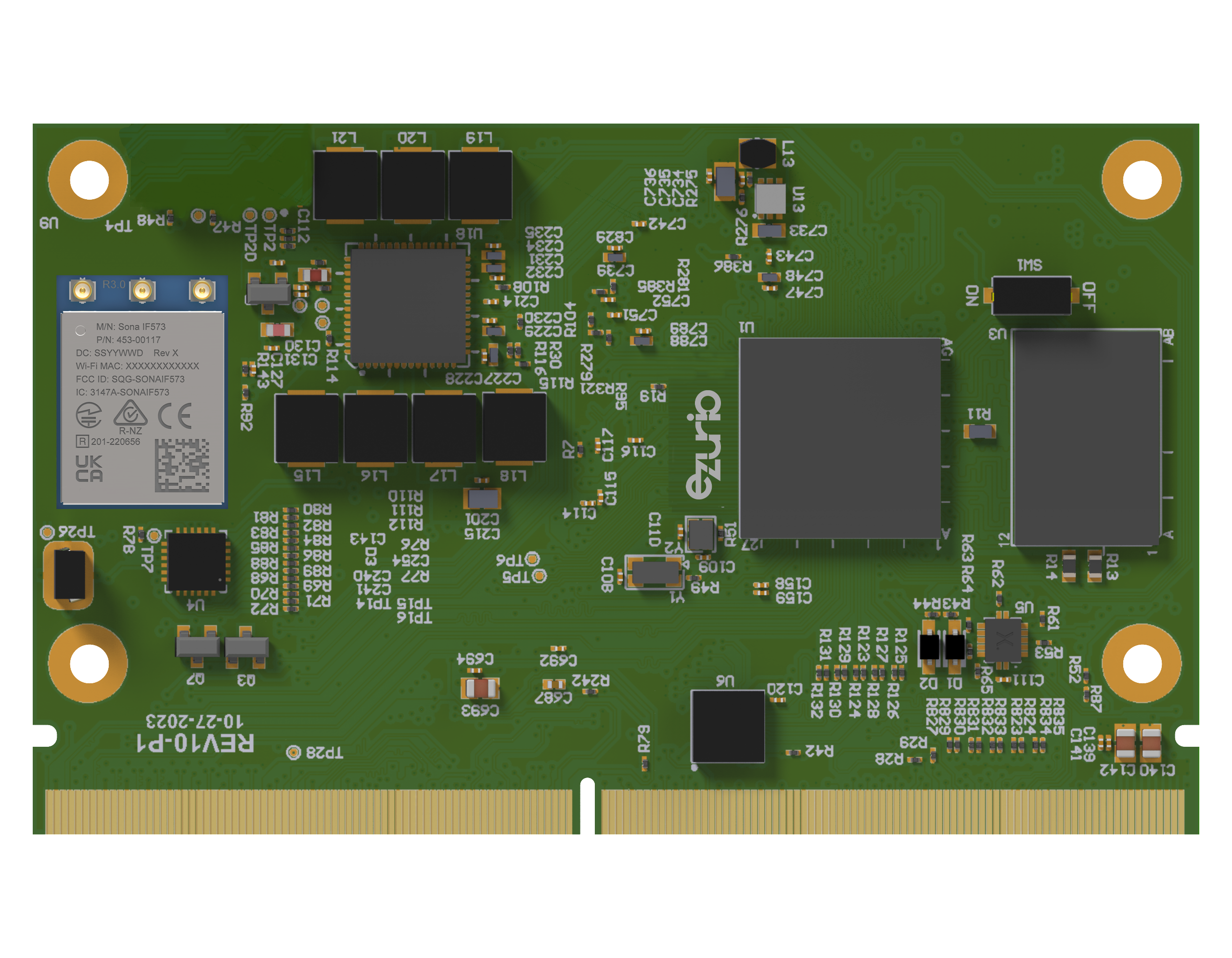

- Operational Efficiency: SOMs streamline automation with multitasking and AI capabilities within a standard form factor.

- Increased Productivity: Machines communicate in real-time utilizing Wi-Fi 6 and Bluetooth Classic / LE to help eliminate bottlenecks and downtime.

- Improved Safety: Wireless IoT sensors send data through IoT gateways to the cloud, identifying potential safety hazards.

- Scalable Solutions: As factories advance, machinery also needs to progress. Use of interchangeable modules and SOMs offer ability to easily use the latest technological solutions.

Interested in transforming your facility and devices? Talk to an Ezurio expert today.

Talk to an Expert

/filters:background_color(white)/2024-03/AI-Driven%20Predictive%20Maintenance%20Improves%20Digital%20Factories.png)

/filters:background_color(white)/2024-04/04%20-%20Premium%20Wi-Fi%20Advantage.png)

/filters:background_color(white)/2024-04/An%20Engineer%27s%20Guide%20to%20Industrial%20HMIs%20Cover%20Image.png)

/filters:background_color(white)/2024-03/Application%20Study%20Industrial%20Predictive%20Maintenance%20White%20Paper-V2-Cover-1.png)

/filters:background_color(white)/2024-03/UWB-White-Paper-V2-Cover-1.png)

/filters:background_color(white)/2024-03/Digital%20Twin%20Technology%20Transforms%20Factories.png)

/filters:background_color(white)/2023-09/indusrial-medical-wifi-6-6e-webinar.png)

/filters:background_color(white)/2023-06/Laird_RegImage_7_12_231.64790ae56.png)

/filters:background_color(white)/2024-03/Leveraging%20UWB%20and%20BLE%20in%20Manufacturing%20Environments.png)

/filters:background_color(white)/2024-02/Tungsten700%20Blog%20Industrial%20Use%20Case%20Cover%20Image.png)