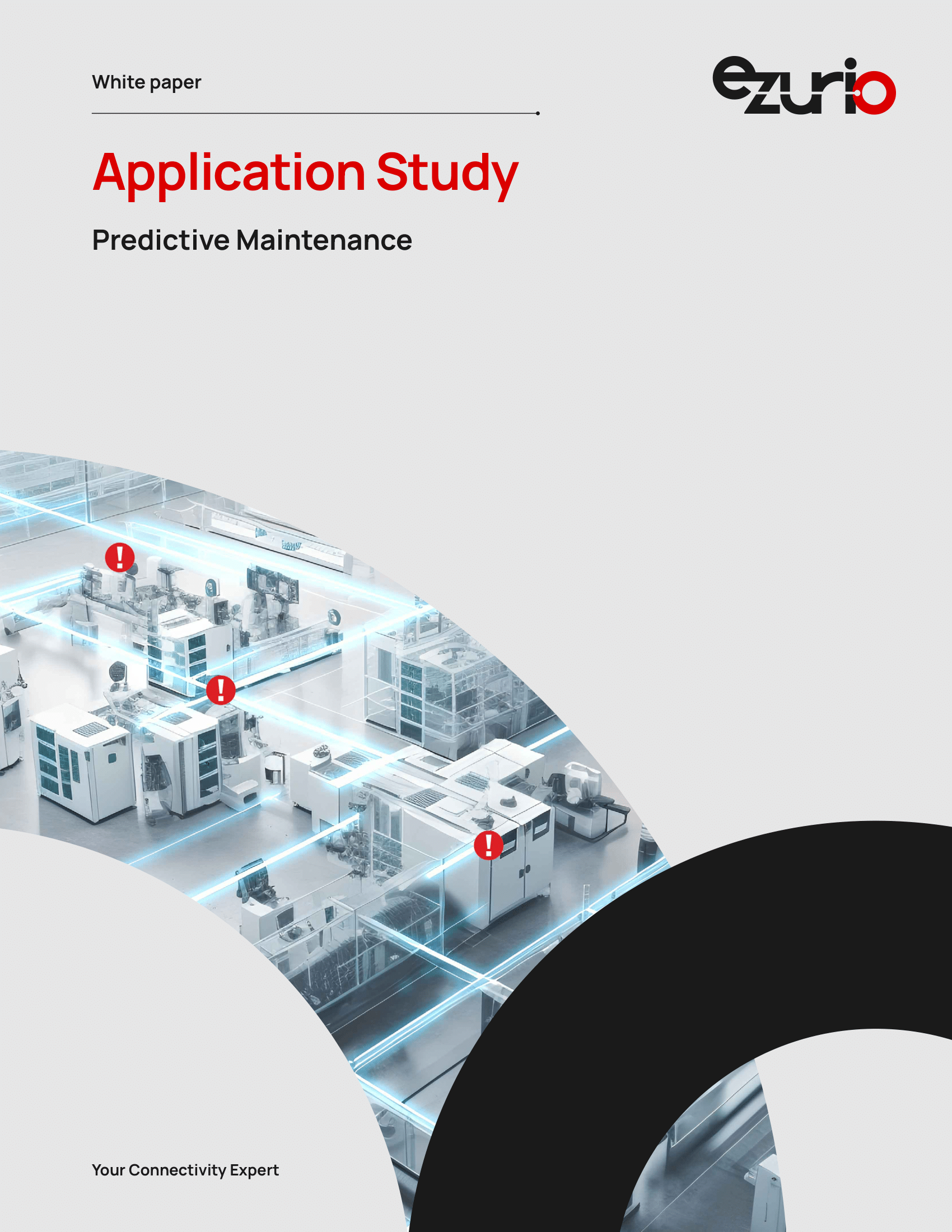

Use Case: Smart Factory

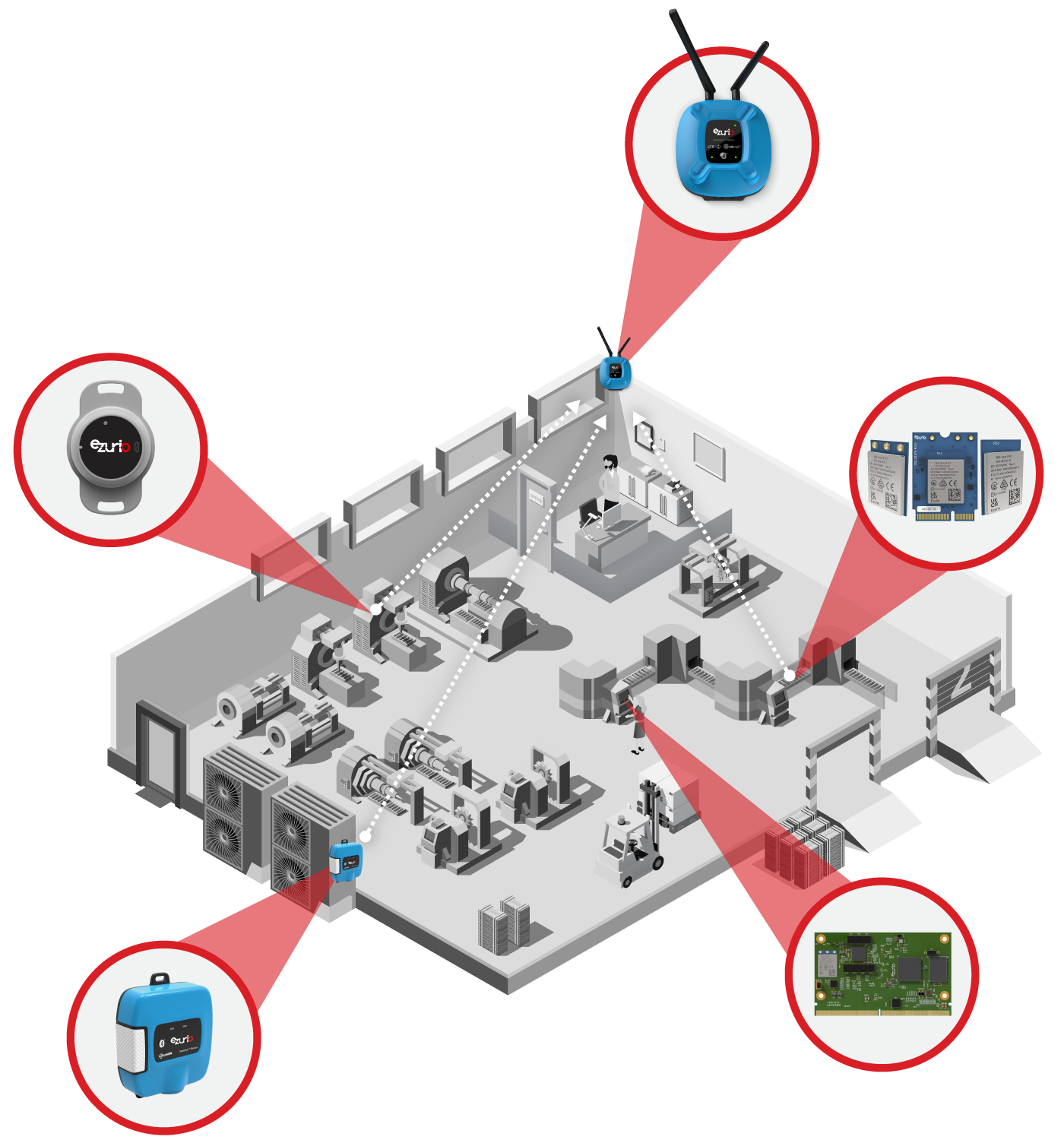

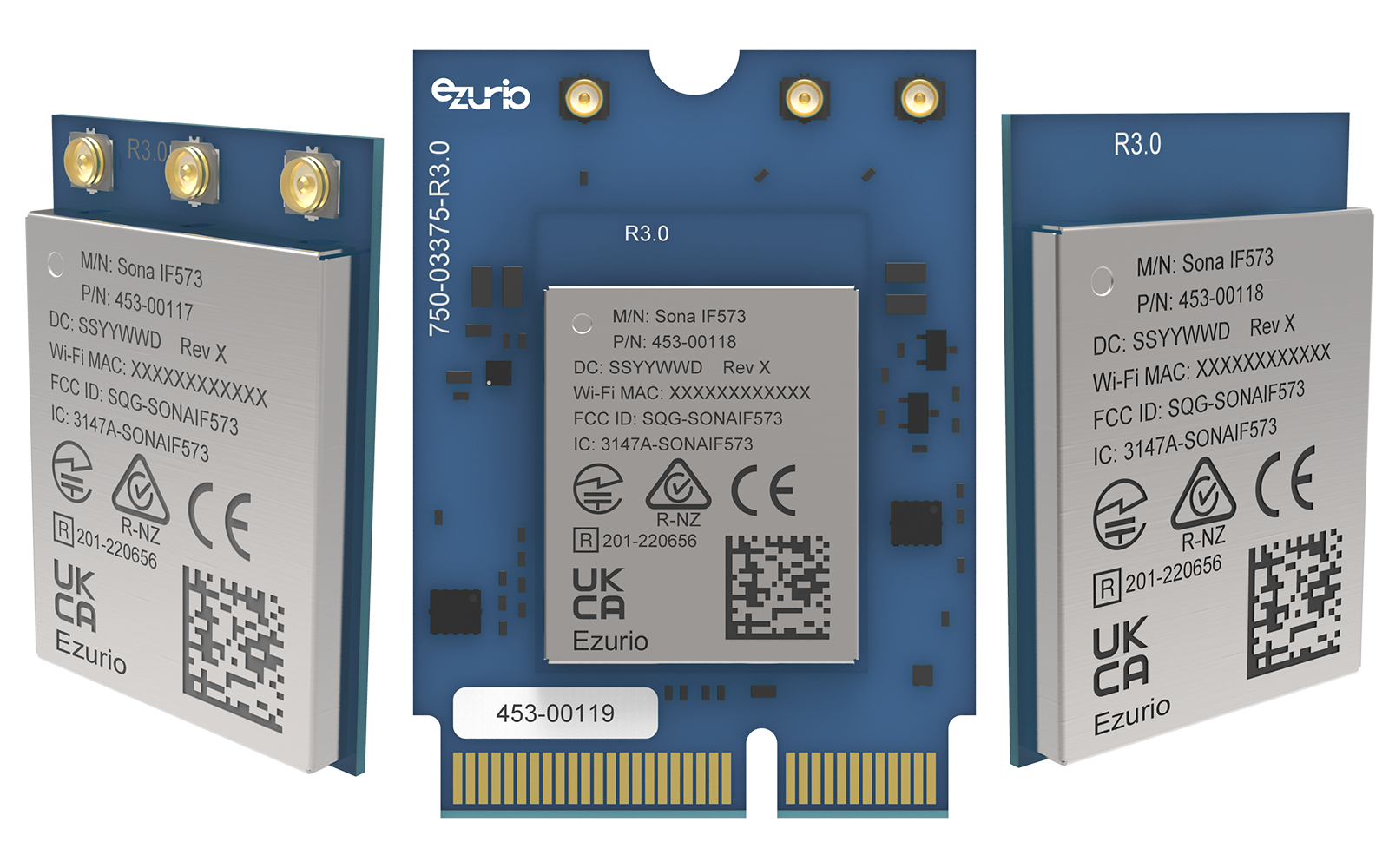

A smart factory never sleeps, every machine is synchronized to 24/7 production. Today, through the power of predictive maintenance, unplanned downtime once a major obstacle to productivity, is now being prevented by IoT devices. These devices, equipped with Wi-Fi, Bluetooth, LoRaWAN, and wireless system-on-modules, don't just watch over the machinery; they gather and wirelessly transmit critical sensor data, allowing operators to monitor the factory's health in real-time.

Operators can now detect potential issues before they escalate, scheduling maintenance without interrupting production flow. The result? Reducing maintenance costs and unplanned failures by up to 50%.

Key Ezurio Advantages:

- Enhanced Uptime: minimize disruptions with targeted maintenance strategies.

- Continuous Monitoring: stay informed with 24/7 factory conditions using Ezurio's wireless modules..

- Robust Connectivity: depend on our industrial-grade wireless solutions to enhance signal reliability in harsh environments.

- Strategic Maintenance Planning: leverage predictive analytics to reduce maintenance costs with efficient scheduling

- Economic Efficiency: not only prevent repairs, optimize your financial resources. Reallocate your maintenance budget towards innovation and growth.

Need help with wireless connectivity and embedded solutions?

Talk to an Expert

/filters:background_color(white)/2024-03/AI-Driven%20Predictive%20Maintenance%20Improves%20Digital%20Factories.png)

/filters:background_color(white)/2024-03/Application%20Study%20Industrial%20Predictive%20Maintenance%20White%20Paper-V2-Cover-1.png)

/filters:background_color(white)/2024-03/UWB-White-Paper-V2-Cover-1.png)

/filters:background_color(white)/2024-03/Digital%20Twin%20Technology%20Transforms%20Factories.png)

/filters:background_color(white)/2024-10/Predictive%20Maintenance%20Application%20Story-New%20Template%20Design.png)