/filters:background_color(white)/2024-03/Robotics-White-Paper-V2-Cover-1.png)

AGVs, AMRs, Cobots and Connectivity: Accelerating Wireless Design for Next-Gen Industrial Robotics

The next-generation of robots depend on reliable, robust, secure wireless connectivity.

The integration of wireless connectivity in robotics is setting a new benchmark across various industries, enhancing operational efficiency, safety, and productivity. With a trusted partner, Ezurio’s (formerly Laird Connectivity) broad range of products, including embedded modules, antennas, sensors, and gateways, is pivotal in optimizing robotics operations.

Market Size

# of Robots

CAGR

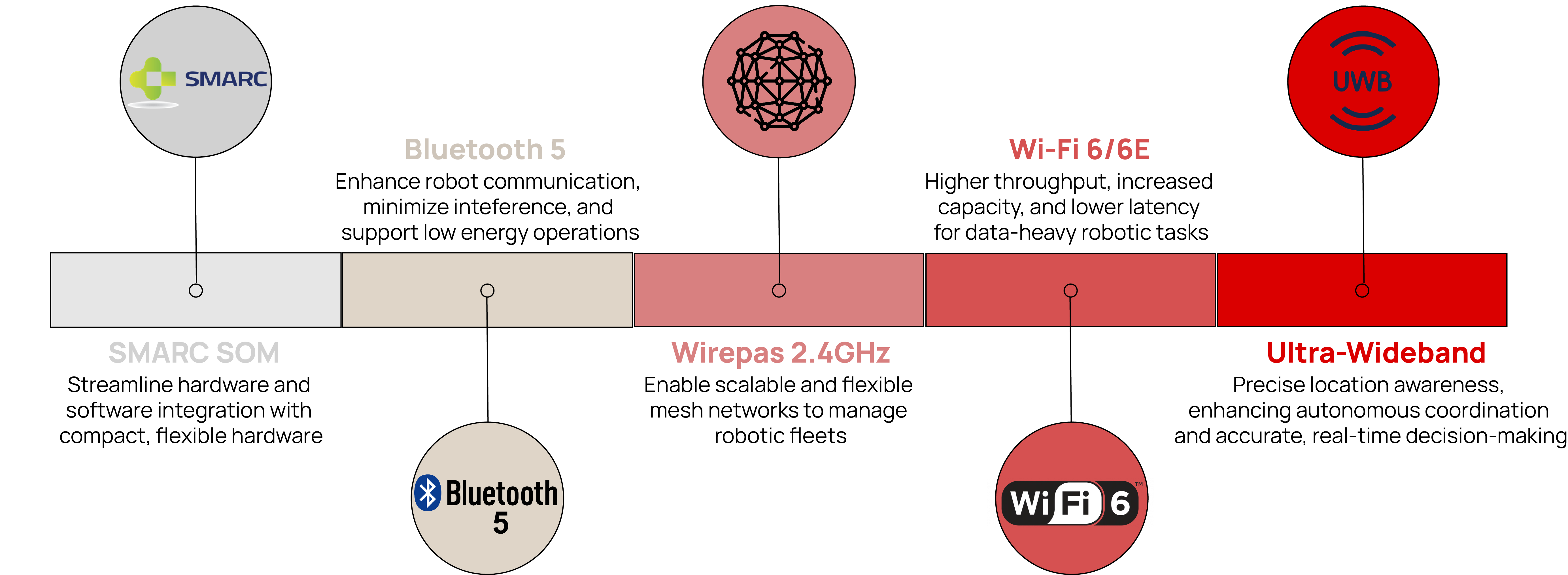

Advancements in wireless connectivity are pivotal to solving challenges faced with next-generation robots. With the integration of technologies such as Wi-Fi 6/6E and Bluetooth 5, robots are experiencing enhanced communication, minimized interference, and boosted data handling capabilities. Alongside Ultra-Wideband (UWB) and Mesh technology, these technologies help facilitate accurate real-time location tracking and robust network coverage, essential for smooth robot collaboration.

The industrial robots of yesterday were transformative, but the capabilities and complexities of today's autonomous systems surpass anything we have seen. It's not about performing predefined tasks anymore; it's about making decisions, navigating dynamically, and working safely alongside humans.

Read our white paper to explore how Wi-Fi 6 / 6E and system on modules are overcoming the unique hurdles experienced by this generation of robots.

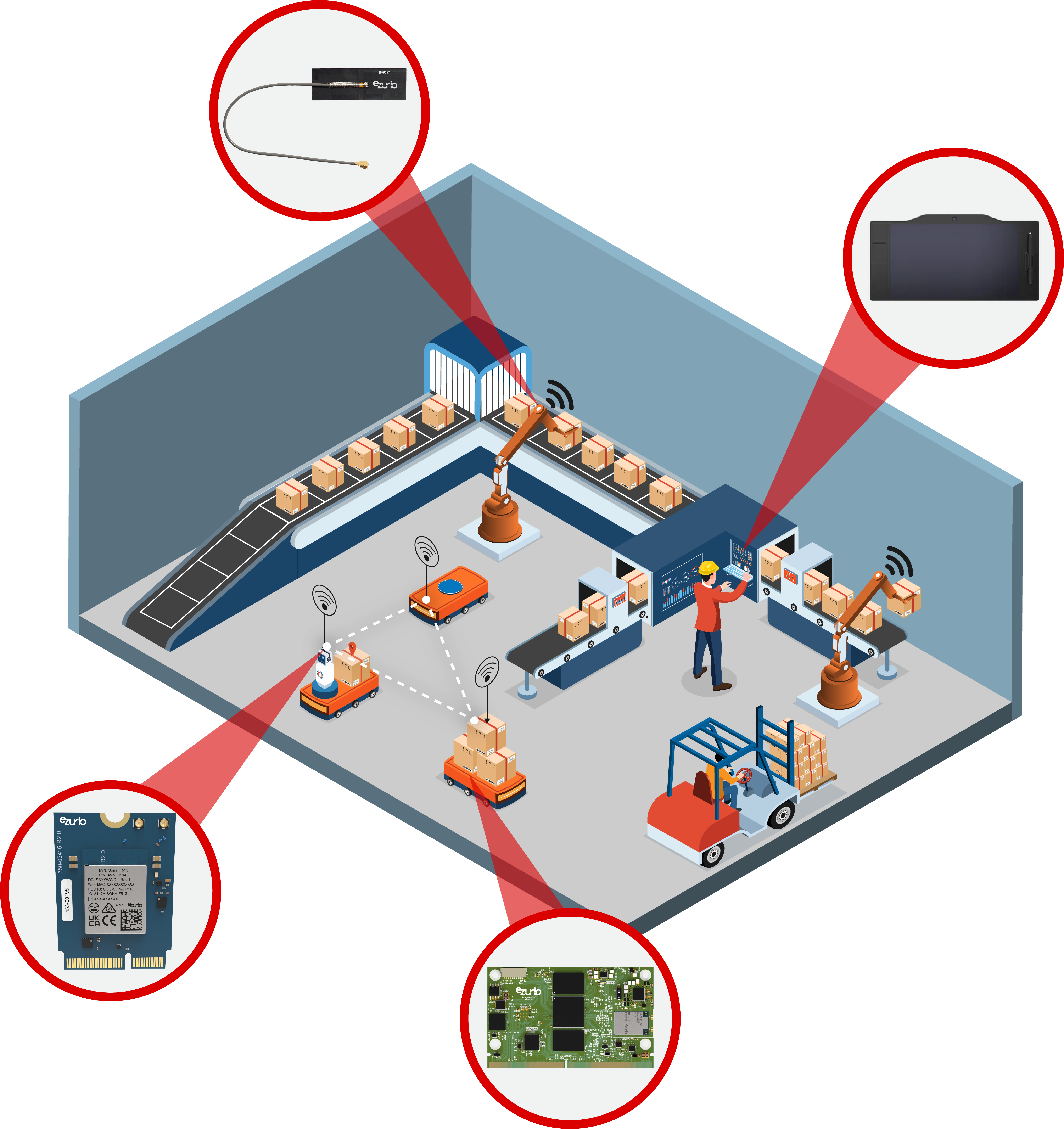

Robotics are improving efficiency, precision, and safety across assembly lines. They have transformed manufacturing processes as AGVs, AMRs, and Cobots take on labor-intensive and repetitive tasks to decrease the number of errors and injuries.

Ezurio’s wireless and embedded systems play a crucial role improving communication and coordination between robots. Our solutions ensure reliable and secure data transmission, allowing for real-time and autonomous decision-making even in noisy RF environments. This allows for a scalable, secure incorporation of robotics into manufacturing processes. Through Ezurio’s products, we not only promote a smarter, more responsive robotic workforce, but also set the stage for ongoing innovation in AI, edge computing, and human-robot collaboration.

Key Ezurio Advantages:

Need help with wireless connectivity and embedded solutions?

The demand for online shopping with quick turnaround delivery has never been higher. Fulfillment centers face many challenges like excessive amounts of manual labor, error-prone processes, and difficulty adapting to changing layouts. These challenges lower the facility’s productivity in processing orders and meeting quotas.

Read this paper to learn how Ezurio's (formerly Ezurio) products help robots to process, analyze, and perform tasks in real-time to improve productivity and efficiency in fulfillment centers.

/filters:background_color(white)/2024-03/Robotics-White-Paper-V2-Cover-1.png)

The next-generation of robots depend on reliable, robust, secure wireless connectivity.

/filters:background_color(white)/2024-03/UWB-White-Paper-V2-Cover-1.png)

UWB’s moment in the sun has been a long time coming, which makes its surging use cases and adoption all the more remarkable.

/filters:background_color(white)/2023-10/Electronic%20Design%20Mediatek%20Webinar%20Image.jpg)

A November 14th Electronic Design-hosted webinar sponsored by Laird Connectivity and MediaTek Genio

/filters:background_color(white)/2024-03/Leveraging%20UWB%20and%20BLE%20in%20Manufacturing%20Environments.png)

Manufacturing processes are being revolutionized by pin-point tracking and monitoring, leading to optimized workflows and enhanced safety protocols within the factory environment.

/filters:background_color(white)/2024-03/Mobile%20Robots%20Improve%20Productivity%20for%20Fulfillment%20Centers.png)

From the facility floor to your doorstep, the journey of a product is being reimagined. Utilizing AGVs, AMRs, and collaboration of cobots, step into the new era of fulfillment.

/filters:background_color(white)/2023-09/AdobeStock_1820006341.jpeg)

You’re probably familiar with UWB as the location technology made famous by consumer devices such as Apple AirTags. But this technology is broadly applicable as a solution to MANY problems – and in many industries as well.