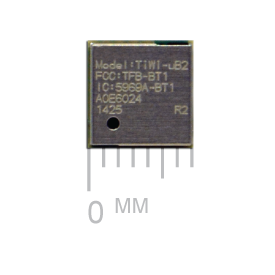

TiWi-uB2 Bluetooth Module

Overview

Bluetooth Smart Ready Module

The TiWi-uB2 Bluetooth module is a high performance 2.4 GHz Bluetooth 2.1+EDR and Bluetooth Low Energy (LE) - Smart Ready radio in a cost effective, pre-certified footprint. The highly integrated TiWi-uB2 module makes the use of Bluetooth headsets and other applications possible. This module fully supports the dual mode Bluetooth and Bluetooth LE operation, and the output power can support class 1.5. The SIP module provides UART interface/audio PCM interface for Bluetooth through the HCI transport layer.

The SIP module is specifically developed for Smart phones and Portable devices.

Buy Now

Development Kits

-

/filters:background_color(white)/404.png?product_icon)

450-0105

End of Life (EOL)Additional DescriptionTiWi-uB2 EM BoardAntenna TypeExternalLogical InterfacesSerial, PCM

Specifications

Controller and Host

GAP - Central, Peripheral, Observer, or Broadcaster

ATT / GATT - Client and Server

SMP - AES - 128 Encryption and Decryption

L2CAP

-85 dBm, 8DPSK at 0.01% BER

30.2 mA, DH1 Packet

13.0 mA, DH5 Packet

VBAT Max, VDD_IO Max: 4.8 V to 1.92 V

Part Number

| Price @ 1k

| Additional Description

| Antenna Type

| Chipset (Wireless)

| Frequency Range (Max)

| Frequency Range (Min)

| Logical Interfaces

| OS/Software

| Product Type

| System Architecture

| Technology

|

|---|---|---|---|---|---|---|---|---|---|---|---|

450-0104 EOL Buy Options | N/A | TiWi-uB2 Module, Tray | External | TI CC2564 | 2480 MHz | 2402 MHz | Serial, PCM | HCI | Embedded Module | Hosted | Bluetooth 2.1 + EDR, Dual Mode (Classic + BLE) |

450-0104R EOL Buy Options | N/A | TiWi-uB2 Module, TR | External | TI CC2564 | 2480 MHz | 2402 MHz | Serial, PCM | HCI | Embedded Module | Hosted | Bluetooth 2.1 + EDR, Dual Mode (Classic + BLE) |

Documentation

Product Brief 1 total

Name |

Part |

Last Updated |

|---|---|---|

| Product Brief - TiWi-uB2 | All | 09/05/2024 |

Datasheet 1 total

Name |

Part |

Last Updated |

|---|---|---|

| Datasheet - TiWi-uB2 | All | 09/05/2024 |

Software 5 total

Name |

Part |

Last Updated |

|---|---|---|

| Bluetooth Eval Tool | All | 03/29/2019 |

| Bluetooth Patch File: ETSI BT 4.0 all certified antennas | All | 03/29/2019 |

| Bluetooth Patch File: FCC/IC/ETSI BT 2.1 + EDR, FCC/IC BT 4.0 all certified antennas | All | 03/29/2019 |

| Bluetooth Patch File: Used with the Bluetooth Eval Tool | All | 03/29/2019 |

| WLAN and Bluetooth Radio Tools User Guide | All | 05/01/2019 |

Documentation 3 total

Name |

Part |

Last Updated |

|---|---|---|

| Antenna Design Guide | All | 03/29/2019 |

| EM Board User Guide | All | 03/29/2019 |

| EOL Notice - TiWi-uB1 and TiWi-uB2 - Oct 2023 | All | 11/13/2023 |

Certification 3 total

Name |

Part |

Last Updated |

|---|---|---|

| EU Certifications - TiWi-uB2 | All | 05/17/2021 |

| FCC Certifications - TiWi-uB2 | All | 05/17/2021 |

| Regulatory Information - TiWi-uB2 | All | 05/18/2021 |

Technical Drawings 3 total

Name |

Part |

Last Updated |

|---|---|---|

| 3D Models CAD Downloads (8-11-2012)(450-0104) | All | 03/29/2019 |

| EM Board CAD Download (12-3-2012) (450-0105) | All | 03/29/2019 |

| SCH/PCB Models CAD Downloads (12-3-2012)(450-0104) | All | 03/29/2019 |

Quality and Environmental 7 total

Name |

Part |

Last Updated |

|---|---|---|

| Bluetooth SIG Listing | All | 03/29/2019 |

| Conflict Minerals Statement | All | 08/09/2024 |

| EU RoHS (2011/65/EU) | All | 03/29/2019 |

| FCC Bluetooth Grant | All | 03/29/2019 |

| Product Change Notice (TiWi-uB2) | All | 03/29/2019 |

| Reach Chemical Analysis | All | 03/29/2019 |

| WEEE Statement | All | 03/29/2019 |

Become an Ezurio Customer to Gain Exclusive Access to Our Design Experts

- Antenna Scans

- Antenna selection and placement

- Custom antenna design

- Worldwide EMC testing / certifications

- Embedded RF hardware / firmware design

- Cloud architecture and integration

- Mobile application development

- Product & Industrial Design

Distributors

| Distributor | Phone Number | Region | Website |

|---|---|---|---|

| Arrow Electronics | 1-855-326-4757 +44 2039 365486 |

APAC, North America, South America, EMEA | Website |

| Braemac Australia, New Zealand, South East Asia | +61 2 9550 6600 +64 9 477 2148 |

APAC | Website |

| DigiKey | 1-800-344-4539 |

North America, South America, APAC, EMEA | Website |

| EBV Elektronik | EMEA | Website | |

| Farlink Technology China, Hong Kong | +86 13266922199 |

APAC | Website |

| Farnell | 1-800-936-198 +44 3447 11 11 22 |

EMEA | Website |

| Future Electronics | 1-800-675-1619 1-514-428-8470 |

North America, South America, APAC, EMEA | Website |

| Glyn | +49-6126-590-0 |

EMEA | Website |

| Hy-Line Germany Only | +49 89 614 503 0 |

EMEA | Website |

| Jetronic China, Hong Kong and Taiwan | 852-27636806 |

APAC | Website |

| M2M Germany | +49-6081-587386-0 |

EMEA | Website |

| Martinsson | +46 8 7440300 |

EMEA | Website |

| McCoy South East Asia | +65 6515 2988 |

APAC | Website |

| Mouser Electronics | 1-800-346-6873 +44 1494 427500 |

North America, South America, APAC, EMEA | Website |

| RS Components | +852-2421-9898 +44 3457-201201 |

North America, South America, APAC, EMEA | Website |

| Ryoyo Japan | +81-3-3543-7711 |

APAC | Website |

| Solsta UK Only | +44 (0) 1527 830800 |

EMEA | Website |

| Supreme Components International India, South East Asia | +65 6848-1178 |

APAC | Website |

| Symmetry Electronics | 1-866-506-8829 |

North America | Website |

| Tekdis Australia and New Zealand | +61 3 8669 1210 |

APAC | Website |

| Telsys | +972 3 7657666 |

EMEA | Website |

| WPG | +44 1628 958460 |

EMEA | Website |

Laird Connectivity is now Ezurio

Laird Connectivity is now Ezurio

/filters:background_color(white)/2024-10/tiwi-ub2-bluetooth-smart-ready-module-front1.jpg)