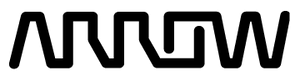

BL653μ Series - Bluetooth 5.4 + 802.15.4 + NFC Modules

Overview

Reliable Bluetooth Connectivity for the IoT - Just a Fraction of the Size.

Ezurio’s latest range of Nordic nRF52833 based modules specifically targets OEMs where space is constrained in their designs. Yet still the miniaturized BL653μ series enables Industrial OEMs to robustly implement longer range Bluetooth LE applications in the harshest operating environments. This series of secure, low power microcontroller modules with multi wireless capabilities is the future of wireless Internet of Things (IoT) connectivity, as small as 6.3 x 5.6 mm.

Powered by Nordic’s nRF52833 WLCSP silicon, the small form factor BL653μ modules provide for secure, robust Bluetooth Low Energy and a Cortex -M4F CPU for any OEM’s product design. The BL653μ provides you with maximum development flexibility with programming options for the Nordic SDK or Zephyr RTOS, a simple, intuitive AT command set, as well as Ezurio’s own smartBASIC environment.

The BL653μ series brings out key nRF52833 hardware features and capabilities including USB access, up to +8 dBm transmit power, up to 5.5V supply considerations, and NFC tag (type 2 / 4) implementation. Complete regulatory certifications enable faster time to market and reduced development risk completes Ezurio’s simplification of your next small form factor Bluetooth design!

Buy Now

Ultra-Compact and Highly Flexible

Our BL653μ Series modules bring reliably, high-quality Bluetooth 5.4 to our smallest form factor ever. With an optional chip antenna or antenna trace pin, they provide multiple ways to connect and develop at an incredibly small size.

- Chip Antenna (453-00059) - 6.3 x 8.6 x 1.6 mm

- Trace Pin (453-00060) - 6.3 x 5.6 x 1.6 mm

Specifications

Trace Pin (453-00060)

Nordic nRFConnect (Android/iOS Application)

6.3 x 5.6 x 1.6 mm (Trace Pad Module)

111 dB (@ LE 125 Kbps)

Max Peak Radio Current (@0 dBm TX) - 4.9 mA (DCDC at 3V)

-103 dBm (typical @ LE 125 Kbps)

Thread supported via Zephyr RTOS

| Part Number | Price @ 1K | Antenna Type | Bulk or Single | Chipset (Wireless) | Frequency Range (Max) | Frequency Range (Min) | Logical Interfaces | OS/Software | Packaging | Product Type | System Architecture | Technology | Type |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

453-00059CBuy Options | N/A | Integrated Antenna | Bulk | Nordic nRF52833 WLCSP | 2480 MHz | 2402 MHz | UART, GPIO, ADC, PWM, PDM, FREQ output, I2C, SPI, NFC, USB | smartBASIC, Zephyr, Nordic SD, AT Commands | Cut Tape | Embedded Module | Hostless | Bluetooth 5.4 | |

453-00059RBuy Options | N/A | Integrated Antenna | Bulk | Nordic nRF52833 WLCSP | 2480 MHz | 2402 MHz | UART, GPIO, ADC, PWM, PDM, FREQ output, I2C, SPI, NFC, USB | smartBASIC, Zephyr, Nordic SD, AT Commands | Tape/Reel | Embedded Module | Hostless | Bluetooth 5.4 | |

453-00060CBuy Options | N/A | Trace Pin | Bulk | Nordic nRF52833 WLCSP | 2480 MHz | 2402 MHz | UART, GPIO, ADC, PWM, PDM, FREQ output, I2C, SPI, NFC, USB | smartBASIC, Zephyr, Nordic SD, AT Commands | Cut Tape | Embedded Module | Hostless | Bluetooth 5.4 | |

453-00060RBuy Options | N/A | Trace Pin | Bulk | Nordic nRF52833 WLCSP | 2480 MHz | 2402 MHz | UART, GPIO, ADC, PWM, PDM, FREQ output, I2C, SPI, NFC, USB | smartBASIC, Zephyr, Nordic SD, AT Commands | Tape/Reel | Embedded Module | Hostless | Bluetooth 5.4 | |

453-00062-K1Buy Options | N/A | None | Programming Kit | USB-SWD Programming Kit: Includes mainboard, TC2050-IDC Tag Connect cable, 10-pin flat IDC cable, 1.2 m USB cable, and 2-pin jumper |

Documentation

Browse Application Notes, Certifications, Datasheets, Documentation, Legacy Materials, Product Briefs, Software and Technical Drawings in our Support & Documentation Center.

What is the correct syntax for filtering with the AT+LSCN command?

When working with the AT Interface firmware, central role devices can filter scan results by using the following optional parameters with the AT+LSCN command.

AT+LSCN (timeout),(escaped pattern), (rssi)

- timeout_ sec: configures how long the module will scan before it timesout

- escaped_pattern : filters the adverts in the scan results for a pattern in the Device Name. This is case sensitive.

- rssi: filters adverts in the scan results based on the RSSI value

- scan type: Bitmask that sets the type of scan (1MPHY (bit 0 set), LECoded (bit 1 set), Secondary channel scanning (bit 2 set), passive scanning (bit 3 set)

The syntax requires that commas are used to separate each parameter. If not skipping a parameter setting, like "escaped pattern" leave it blank between the commas holding the place for the unused parameter.

Some examples are shown below using a Lyra-S module running the AT Interface firmware:

Example 1: Only setting timeout parameter to 2 seconds

at+lscn 2

AD1:0 003BB937C5B365 -90 ""

ADS:0 003BB937C5B365 -90 "ESLinker-C5B365"

AD1:0 00E2BB9E33B974 -61 ""

ADS:0 00E2BB9E33B974 -61 "ET-3850 Series"

AD1:3 010B16D9226D8C -41 ""

AD1:0 003BB937C5B365 -78 ""

ADS:0 003BB937C5B365 -78 "ESLinker-C5B365"

AD1:0 00E2BB9E33B974 -56 ""

ADS:0 00E2BB9E33B974 -56 "ET-3850 Series"

AD1:0 003BB937C5B365 -78 ""

ADS:0 003BB937C5B365 -78 "ESLinker-C5B365"

AD1:3 01E5ED7A1BA907 -78 ""

AD1:3 010B16D9226D8C -45 ""

AD1:0 003BB937C5B365 -75 ""

ADS:0 003BB937C5B365 -75 "ESLinker-C5B365"

AD1:0 00E2BB9E33B974 -55 ""

ADS:0 00E2BB9E33B974 -55 "ET-3850 Series"

AD1:3 010B16D9226D8C -46 ""

AD1:0 003BB937C5B365 -75 ""

ADS:0 003BB937C5B365 -74 "ESLinker-C5B365"

AD1:3 010B16D9226D8C -46 ""

AD1:0 003BB937C5B365 -89 ""

ADS:0 003BB937C5B365 -89 "ESLinker-C5B365"

AD1:0 00E2BB9E33B974 -61 ""

ADS:0 00E2BB9E33B974 -61 "ET-3850 Series"

AD1:3 010B16D9226D8C -41 ""

AD1:3 010B16D9226D8C -41 ""

AD1:0 003BB937C5B365 -78 ""

ADS:0 003BB937C5B365 -78 "ESLinker-C5B365"

AD1:0 00E2BB9E33B974 -56 ""

ADS:0 00E2BB9E33B974 -56 "ET-3850 Series"

AD1:3 010B16D9226D8C -45 ""

AD1:3 011824EF90B41E -88 ""

AD1:0 003BB937C5B365 -75 ""

ADS:0 003BB937C5B365 -75 "ESLinker-C5B365"

AD1:3 010B16D9226D8C -46 ""

AD1:0 00E2BB9E33B974 -55 ""

ADS:0 00E2BB9E33B974 -55 "ET-3850 Series"

AD1:3 010B16D9226D8C -41 ""

AD1:0 00E2BB9E33B974 -61 ""

ADS:0 00E2BB9E33B974 -61 "ET-3850 Series"

AD1:0 003BB937C5B365 -75 ""

ADS:0 003BB937C5B365 -75 "ESLinker-C5B365"

AD1:0 003BB937C5B365 -90 ""

ADS:0 003BB937C5B365 -90 "ESLinker-C5B365"

AD1:0 0018C293029337 -45 "LYRA-029337"

ADS:0 0018C293029337 -45 ""

AD1:0 00E2BB9E33B974 -61 ""

AD1:3 010B16D9226D8C -45 ""

AD1:0 00E2BB9E33B974 -56 ""

ADS:0 00E2BB9E33B974 -56 "ET-3850 Series"

OK

Example 2: Only setting "escaped pattern" parameter * (uses default timeout parameter set at S Reg 106)

at+lscn ,"LYRA"

AD1:0 0018C293029337 -48 "LYRA-029337"

AD1:0 0018C293029337 -46 "LYRA-029337"

AD1:0 0018C293029337 -51 "LYRA-029337"

AD1:0 0018C293029337 -48 "LYRA-029337"

AD1:0 0018C293029337 -45 "LYRA-029337"

AD1:0 0018C293029337 -51 "LYRA-029337"

AD1:0 0018C293029337 -49 "LYRA-029337"

AD1:0 0018C293029337 -44 "LYRA-029337"

AD1:0 0018C293029337 -53 "LYRA-029337"

AD1:0 0018C293029337 -49 "LYRA-029337"

AD1:0 0018C293029337 -46 "LYRA-029337"

AD1:0 0018C293029337 -53 "LYRA-029337"

AD1:0 0018C293029337 -49 "LYRA-029337"

AD1:0 0018C293029337 -53 "LYRA-029337"

AD1:0 0018C293029337 -49 "LYRA-029337"

AD1:0 0018C293029337 -45 "LYRA-029337"

AD1:0 0018C293029337 -53 "LYRA-029337"

AD1:0 0018C293029337 -49 "LYRA-029337"

AD1:0 0018C293029337 -44 "LYRA-029337"

AD1:0 0018C293029337 -53 "LYRA-029337"

OKExample 3: Only setting time_out and RSSI parameters

at+lscn 2,,-60

AD1:3 010784D7B7E8C0 -47 ""

AD1:3 010784D7B7E8C0 -46 ""

AD1:3 010784D7B7E8C0 -46 ""

AD1:3 010784D7B7E8C0 -42 ""

AD1:0 00E2BB9E33B974 -57 ""

ADS:0 00E2BB9E33B974 -57 "ET-3850 Series"

AD1:3 010784D7B7E8C0 -47 ""

AD1:0 00E2BB9E33B974 -56 ""

ADS:0 00E2BB9E33B974 -56 "ET-3850 Series"

AD1:3 010784D7B7E8C0 -46 ""

AD1:0 00E2BB9E33B974 -57 ""

ADS:0 00E2BB9E33B974 -57 "ET-3850 Series"

AD1:3 010784D7B7E8C0 -42 ""

AD1:0 00E2BB9E33B974 -57 ""

ADS:0 00E2BB9E33B974 -57 "ET-3850 Series"

AD1:3 010784D7B7E8C0 -46 ""

AD1:0 00E2BB9E33B974 -57 ""

ADS:0 00E2BB9E33B974 -57 "ET-3850 Series"

AD1:3 010784D7B7E8C0 -45 ""

OK

Example 4: Setting scan type parameter to scan for both 1MPHY and LECoded for 1 second

at+lscn 1,,,3

AD1:0 003BB937C5B365 -75 ""

ADS:0 003BB937C5B365 -75 "ESLinker-C5B365"

AD1:0 00E2BB9E33B974 -55 ""

ADS:0 00E2BB9E33B974 -56 "ET-3850 Series"

AD1:3 0113319782410E -79 ""

AD1:0 00E2BB9E33B974 -54 ""

ADS:0 00E2BB9E33B974 -55 "ET-3850 Series"

AD1:0 003BB937C5B365 -75 ""

ADS:0 003BB937C5B365 -75 "ESLinker-C5B365"

AD1:3 011991A5463397 -41 ""

AD1:0 003BB937C5B365 -73 ""

ADS:0 003BB937C5B365 -73 "ESLinker-C5B365"

AD1:3 011991A5463397 -45 ""

AD1:0 00E2BB9E33B974 -58 ""

ADS:0 00E2BB9E33B974 -58 "ET-3850 Series"

AD1:3 011991A5463397 -45 ""

AD1:0 003BB937C5B365 -73 ""

ADS:0 003BB937C5B365 -73 "ESLinker-C5B365"

AD1:0 003BB937C5B365 -84 ""

ADS:0 003BB937C5B365 -84 "ESLinker-C5B365"

AD1:3 011991A5463397 -46 ""

AD1:0 00E2BB9E33B974 -55 ""

ADS:0 00E2BB9E33B974 -55 "ET-3850 Series"

AD1:0 003BB937C5B365 -84 ""

ADS:0 003BB937C5B365 -85 "ESLinker-C5B365"

AD1:3 011991A5463397 -42 ""

AD1:0 003BB937C5B365 -75 ""

ADS:0 003BB937C5B365 -75 "ESLinker-C5B365"

OK

Does the BL653 support external circuitry on VDD using high voltage mode?

The nRF52833 used on the BL653 module does not incorporate the internal circuitry from the REG0 output to support external loading on VDD when the module is configured for High Voltage Mode. When in Power Off mode there may be issues with the POR circuit if current is drawn from REG0.

Does Ezurio provide breakout boards for its Bluetooth modules?

Ezurio did provide breakout boards for our older BL600(EOL) modules but we do not produce breakout boards for any of our current range of Bluetooth modules as of 2024.

This includes all BL65x, BL53xx, BL54xxx, BTxxx, Vela and Lyra modules.

We do provide development kits for all of our module offerings. To learn more, visit any product page on ezurio.com.

When working with AT Interface, or vSP UART Bridge example applications, how can I break out of a vSP UART bridge connection using the ^^^^ escape sequence in UwTerminalX with the 250ms delay specified, as it does not seem to be working?

When working with UwTerminalX, note that by default LineMode is enabled. With LineMode enabled, any data entered is not sent until the [Enter] key is pressed, as shown below:

To break the connection you must first disable LineMode, then when each character is entered it will be sent immediately over the bridge connection, without the need to press the [Enter] key. Now when four ^ are entered with a slight delay, the first three will be sent over the bridge connection, but the fourth one will break the connection, as shown below:

Can I store multiple “$autorun$” files on the BL65x?

The BL65x's SmartBASIC is designed to support and execute only one “$autorun$” application, identified by the filename "$autorun$". If a new autorun file is uploaded, it will replace the existing one, preventing the original “$autorun$” code from being executed.

However, it is possible to store multiple application codes under different filenames. Be mindful of the memory space constraints to ensure you do not exceed the available storage.

More information about “$autorun$” could be found under section 3.4.4 Autorun in the CS-GUIDE-smartBASIC-CoreFunctionality_v3_5.pdf

In smartBASIC, how can I increase the max message size above 20 bytes on a BL65x module?

One of the major additions in Bluetooth v4.2 is LE Data Packet Length Extension. This feature allows the BLE packet size to increase from 27 to 251 bytes in the link layer, therefore significantly increasing the capacity of the data channel.

In order to take full advantage of the improvements provided by the Packet Length Extension Feature, both devices should be configured to support a larger ATTribute Maximum Transmission Unit (ATT_MTU) and the GATT server characteristic should be configured to support larger Attribute data lengths. The ATTribute Maximum Transmission Unit (ATT_MTU) defines the amount of data a device can send/receive per GATT operation and the Attribute Data Length is the size of the data inside a GATT server as per the image below.

The Application Note: BL65x Data Length Extensions provides additional guidance on how to configure these settings in smartBASIC and references our smartBASIC sample applications which demonstrate the syntax.

Do you support any echoing support in the AT Interface app / implementation such as ATE1 & ATE0 for example?

Both ATE1 and ATE0 commands are pretty common in the modem world which would turn on and off the echo mode. In this case, any typed character(s) will be displayed to the screen or terminal – otherwise they are completely suppressed. This behaviour can be very useful for debugging or in some applications. However, there is currently no support for any echoing in our own AT Interface app and implementation. We recommend (if possible) to use a terminal application as an alternative such as UwTerminalX. In PuTTY, Tera Term or RealTerm this can be configured and enabled if needed.

How can the smartBASIC License key be restored if I get "192A - NVO_NVWORM_EXISTS: The WORM segment already exists and cannot be re-created" error when applying the license using AT+LIC command?

The "192A - NVO_NVWORM_EXISTS: The WORM segment already exists and cannot be re-created" error message indicates that a license key has already been written to the module at some point after the firmware was

flashed, likely an incorrect license key. You can verify this by sending the command ATI 49406 which calls the license key programmed

to the module, followed by the ATI 4 to see if "C0FFEE" appears as the last three bytes of the response returned.

Because

this setting is one time writable in the firmware, if an incorrect license key

has been written, it will be necessary to first erase the flash completely on the module. This can be done using Nordic's nRF Connect for Desktop Programmer

application:

1)

Obtain the correct License Key hash from our Support Team

by connecting the DVK to your PC via the UART interface (USB 1 of the DVK) and getting the

full MAC Address of the module by calling ATI 14. Provide the response to the support team member

so the correct key can be generated.

2)

Connect the DVK to your PC via the SWD (JTAG) interface

(USB2 of the DVK).

3)

Open the Programmer

Application in nRF Connect for Desktop.

4)

Select the Device in the Programmer application.

5)

Select "Erase all".

6)

Reflash the smartBASIC firmware file via the SWD (JTAG) Interface.

7)

Call ATI 49406 to confirm the license key has been erased (should return 00).

8)

Send the AT+LIC "[License Key generated by FAE]"

command to apply the correct smartBASIC license key.

9)

Call ATI 4 - confirm C0FFEE does not appear in the MAC

Address of the module.

When working with AT Interface firmware, what is the correct syntax to use the AT+LSCN command when not wanting to use all the optional parameters?

As

per the AT Interface User Guide, the AT+LSCN

AT+LSCN

Therefore,

the correct syntax for AT+LSCN without using all optional parameters would be

to leave the unused parameters blank (not a "0", just blank) while still dividing

each of the optional parameters using commas. For example, if the only

parameter required is to configure it the scan type (last parameter) to enable

scanning for 1M and Coded PHY (256k) with extended advertisements you would use

the following syntax:

AT+LSCN ,,,7

Please see the AT Interface User Guide for the module you

are working with for more information.

Lyra

Series Modules – AT Interface User Guide

When attempting to enable the external crystal within the smartBASIC code using BleConfigHfClock(1), why does it not change to high speed when calling SYSINFO(2082)?

It is

important to note there are two clock sources, a High Frequency (HF) Clock

source, which is used for clocking the system, and a Low Frequency (LF) Clock

which is primarily used for Sleep Mode. Each of these have options of using an

internal oscillator on the chip, or the specified crystal.

The external 32 MHz crystal for the HF Clock is included on the

module, while the external 32 KHz crystal is an optional LF Clock source which

is NOT included on the module. The optional crystal for the LF Clock source

provides improved protocol timing and helps with radio power consumption when

the radio is in standby doze/deep sleep, by reducing the time that the Rx

window needs to be open.

The BleConfigHfClock() function

within the smartBASIC application is used to select the High Frequency Clock, which is the system clock.

This is the 32MHz crystal, and it can be selected using this BleConfigHfClock()

function.

This is different than the optional external 32kHz Crystal,

which is used as the Low Frequency Clock source. This crystal is typically used

for sleep modes. This can only be selected using the AT+CFG 210 and

cannot be configured within the smartBASIC application. SysInfo 2082 is used to return the Low Frequency

Clock configuration, therefore, it is not affiliated with the High Frequency

Clock setting.

How do you exit Autorun Mode, to enable updating a smartBASIC application OTA or via the UART?

To be able to exit Autorun Mode it is

necessary to include an option in the smartBASIC code, prior to loading it to

the module, that provides a way to exit the application, or have access to the

nAutoRun pin. The options are explained below for UART and OTA methods for

exiting Autorun Mode.

UART Methods:

1) Provided access is available to the nAutoRun pin,

pull the nAutorun pin HIGH to move the module from nAutorun mode to Development

mode. Once this pin is pulled high and the module is reset it should enter into

Interactive Command mode and it should be possible to erase the file system,

using AT&F1 and load a new smartBASIC application over the UART.

2) Have a way to exit the application, via a command or

pin setting, using Endfunc 0. If Waitevent is the last statement in the

application, and a function triggered by the command or pin change returns

"Endfunc 0", then the module will exit the application and return to

Interactive Command mode. Once the module returns to Interactive Command mode,

the file system can be erased with AT&F1, and the updated application can

then be loaded.

Over-the-Air smartBASIC application loading requires

control of the vSP pin. To enter into OTA mode, it is necessary to pull the vSP

pin of the BL65x module high, while the nAutorun pin is held low. This places

the module in vSP-Command Mode, as opposed to vSP-Bridge mode, as explained in

the "Command and Bridge Mode Operation" section of the matching

smartBASIC Extensions User Guide for the module (see links below).

BL654/BL654PA smartBASIC Extensions

Guide v29.5.7.2

User Guide - BL653

and BL653µ smartBASIC Extensions Guide v30.2.3.0

User Guide - BL652

smartBASIC Extensions v28.10.7.2

However, if an $autorun$ application is loaded to the

module when the vSP pin is pulled high it will just run the application, in

which case the one of the following methods can be used to enable exiting the

application and erase the file system so that an updated application can be

loaded.

OTA Methods:

1) Invoke the EraseFileSystem() function in the

smartBASIC application. This function is used to erase the flash file

system which contains the application that invoked this function, if and only

if, the vSP input pin is pulled high. Given that SIO2 is high, after

erasing the file system, the module resets and reboots into command mode with

the virtual serial port service enabled (vSP-Command Mode), and the

application can then be loaded following the OTA method.

2) Have a way to exit the application within the

smartBASIC code, via a command or pin setting, using Endfunc 0. If “Waitevent” is

the last statement in the application, and a function triggered by the command

or pin change returns "Endfunc 0", then the module will exit the

application and return to Interactive Command mode. Once the module returns to

Interactive Command mode, the file system can be erased with AT&F1, and the

updated application can then be loaded.

For convenience, a list of the nAutoRun pins/SIO and

vSP pins/SIO for all BL65x modules is provided below. These can also be found

in the Datasheet for the specified module.

| BL65x nAutoRun and vSP pins | ||

| Module | nAutoRun Pin | SIO |

vSP Pin |SIO |

| BL654PA | Pin 5 SIO_35 |

Pin 50 SIO_02 |

| BL654 | Pin

5 SIO_35 |

Pin

50 SIO_02 |

| BL653 | Pin

34 SIO_35 |

Pin

50 SIO_02 |

| BL653u | Pin

34 SIO_35 |

Pin

37 SIO_02 |

| BL652 | Pin

28 SIO_13 |

Pin

23 SIO_02 |

Does the BL5340, BL5340PA, BL65x and Lyra BLE modules include the DC-DC LC filters on the module?

Yes, all BT modules

include the needed LC filter components required for DC-DC Converter operation.

Lyra P and Lyra S modules include a 2.2uH inductor on VREGSW output and 4.7uF capacitor to ground.

The nRF528xx used on the BL65x modules use two voltage regulators, REG0 and REG1. In Normal Voltage mode only REG1 is enabled. In High Voltage mode both REG1 and REG0 are enabled. The BL65x modules include 10uH and 15nH inductors on DCC output and 1.0uF capacitor to ground on REG1. REG0 includes a 10uH inductor on DCCH output and 4.7uF cap to ground.

Note: The BL651 module uses the nRF52810

which uses a single voltage regulator. The BL651 includes 10uH and 15nH

inductors on DCC output and 1.0uF capacitor to ground.

The nRF5340 used on the BL5340 and BL5340PA modules uses four voltage regulators, Main Voltage Regulator, Radio Voltage Regulator, High Voltage Regulator and a USB Regulator. In Normal Voltage mode the Main Voltage and Radio regulators are enabled while the High Voltage Regulator is disabled. In High Voltage mode the High Voltage regulator is enabled along with the Main Voltage and Radio regulators. The BL5340 module includes a 10uH inductor on the DCC outputs and 1uF capacitor to ground on the Main Voltage and Radio Voltage regulators. The High Voltage regulator includes a 10uH inductor on the DCCH output and 2.2uF capacitor to ground. The USB regulator uses an LDO only an no DC-DC filter components are needed.

How can I change the 32.768KHz Low Power Clock Source using nRF Connect SDK v2.x?

With nRF Connect SDK v2.0.0 and later only VS Code is made

available as an IDE as VS Code provides many features including both Command

Line Interface (CLI) and Graphical User Interface (GUI) in one environment.

Prior to nRF Connect SDK, the 32.768KHz source in nRF5 SDK applications defaulted to using the external crystal oscillator. The BL65x DVK’s populate an external 32.768KHz crystal but it is not connected via open solder bridges. Therefore, either the solder bridges need to be shorted to make the external crystal connection or change the clock source to internal RC Oscillator via the sdk_config.h file.

With nRF Connect SDK the correct 32KHz clock source is selected depending on the EVK. For BL654 DVK examples are built using internal RC oscillator. On BL5340 DVK the external crystal oscillator is selected as the DVK does close the solder bridge pads.

If the 32KHz clock source needs to be changed an application can change accordingly in the prj.conf file of the project. The following direct dependencies need to be added to prj.conf to override the default clock configuration.

External Crystal Oscillator and accuracy selection:

CONFIG_CLOCK_CONTROL_NRF_K32SRC_50PPM=y

Internal RC Oscillator and accuracy selection:

CONFIG_CLOCK_CONTROL_NRF_K32SRC_RC=y

CONFIG_CLOCK_CONTROL_NRF_K32SRC_500PPM=y

Kconfig dependencies can be found:

https://developer.nordicsemi.com/nRF_Connect_SDK/doc/2.3.0/kconfig/index.html

How is a static passkey configured for use in AT Interface Application/Firmware?

Lyra modules must be preloaded with AT Interface firmware, while BL65x modules must be updated to the most current smartBASIC firmware version and programmed with the AT Interface smartBASIC sample application in order to use any AT Interface commands.

To configure a static passkey using AT Interface it is necessary to ensure that the I/O capability of the modules will result in Passkey Entry authentication (per the Bluetooth SIG's IO Capabilities mapping). The Lyra or BL65x module must be configured with the I/O Capability set to Keyboard Only (2) or Keyboard + Display (4), via S Register 107, using the command, ATS 107=x, where x=2 for Keyboard Only or x=4 for Keyboard + Display.

Then the "AT+PKEY " command can be used to issue a static passkey to the underlying stack for use during a pairing procedure in future connections. The passkey must be a 6-digit integer in the range of 000000 – 999999.

The pairing will still use LESC Diffie-Hellman based exchanges. If a randomly generated number is used for the passkey the static passkey will be used.

Note: Pairing using a pre-programmed passkey makes pairing vulnerable to MITM attacks.

For more information on AT Interface configurations please reference the AT Interface User Guide for the specified module series.

Is the command used to set a static passkey with AT Interface firmware, AT+PKEY, persistent through a reset or power-cycle?

The AT+PKEY nnnnnn command, used by AT Interface to configure a static passkey, is an on-the-fly command and will not be persistent through a power-cycle/reset. Only S Register settings, using the ATS & AT%S commands, can be saved using AT&W followed by ATZ. All other AT commands are on-the-fly.

NOTE: Using a static, pre-programmed, passkey makes pairing vulnerable to MITM attacks.

For additional information on configuring a static passkey with AT Interface please refer to the appropriate AT Interface User Guide for the Ezurio module you are working with linked below:

User Guide - AT Interface Application - Lyra Series

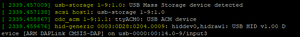

Using STTY with the USB-SWD

These instructions are intended for Linux or Macintosh OS. They may work using WSL, Cigwin, or other bash style terminals in Windows although this is untested.

It may be desired to communicate with a device attached to the USB-SWD without terminal emulation, I.E. Picocom, Screen, Putty. This can be useful for writing bash scripts, or if you're using Zephyr's "west flash" and would like a quick way to check your output.

- Verify you have the program "stty" available using the command "which stty", if this does not return a value you will need to install it. Fortunately "stty" generally comes standard with Linux and MacOS.

- Identify your serial device. This can be done using the command "dmesg -w" then connecting the USB-SWD. You will see output like this (In Linux).

- (Optional) Assign the device name to a variable, for example "DEVICE=/dev/ttyACM0".

- Configure "stty" to talk with the device "stty -F $DEVICE 115200 -echo -echoe -echok"

- To see output from the device execute "cat $DEVICE &". This will send serial communication from the device to Linux's standard output. The "&" is to run this program in the background.

- Now press the reset button on the USB-SWD, you should see the output from your device. In this example the Zephyr "Hello World" example has been flashed to a BT510.

- (Optional) if you would like to send commands back to the device you can use "echo" or add an argument to your shell, "foo() { echo -n -e "$1\r" > $DEVICE; }". Now commands can be issued directly from the command line, for example "foo "my_command"" will send the string "my_command" to the device.

Do the NFC traces need to be controlled differential impedance between NFC1 and NFC2?

The NFC track does not need to be routed with a controlled differential impedance. The NFC antenna is different from the BLE antenna as it's differential and not 50 Ohm (each track is 50 Ohm single ended). Also, the frequency is very low, so the exact impedance doesn't matter as much. The inductance in the antenna is what matters for the NFC antenna. Since the antenna is differential, it's better to use a two-pin connection instead of U.FL which is a single ended connection.

The inductance of the antenna together with the NFC antenna tuning capacitors forms a resonant circuit that is tuned to the NFC frequency, 13.56 MHz. Any change in the connection wires to the antenna can be compensated with the tuning caps.

When working with AT Interface why am I not able to get the module down to 2uA low power mode documented in the Lower Power Mode Application Note?

The Low Power Mode referenced in the following Application Notes are based on running the lp.low.power.deep.sleep.sb sample application which is written specifically for achieving the lowest possible power state of the BL65x module. All of the LEDs on the DVK-BL65x are set to digital out low, the temperature sensor is disabled, and the UART is closed before going into the waitevent. When running the sample application referenced in the document the BL65x module will enter into enter Deep Sleep or Low Power Doze Mode (at waitevent) and achieve the stated low power levels.

Low Power Modes - BL654 v1 1.pdf

Application Note - Low Power Modes - BL654PA

Application Note - BL653 Low Power Modes

Application Note - BL653µ Series - Low Power Modes

BL652 Low Power Modes.pdf

However, if you reference section 3.8 of the AT Interface User Guide you will better understand the nature of the AT Interface application, and why the current consumption is higher even when you are sitting at a waitevent, not entering commands. The Lpuart variant of the AT.Interface smartBASIC application ($autorun$.AT.interface.BL65x.lpuart.sb) can be used to operate the module in doze mode (with the UART closed most of the time) so that the total current consumption can be as low as sub 10 microamps.

Can I pair in vSP Mode with AT Interface Application

Is it possible to bond devices in vSP mode when using the AT Interface application.

In

order to enable the devices to pair and bond in vSP mode, when working

with the AT Interface sample application, you must make the initial

connection in non-vSP mode, using the command, AT+LCON

Once the devices have connected you can pair using the command, AT+PAIR hdlx

command to pair. The pairing will automatically be stored in the

bonding database., Then disconnect the devices and you can now reconnect

in vSP mode using the command ATD

See example with comments following // below:

ati 0 //Calls Device name

BL654

OK

ati 3 //Calls the firmware version on the module

29.5.7.2

OK

ati 4 //Calls the BT ADDR of the module

01F192652D3FB1

OK

ati 2009 //Calls number of devices in Bonding Database

0

OK

at+lcon 01D1C4A981E5E7 //Connects in non-vsp mode with specified BT ADDR

connect 1,01D1C4A981E5E7,15000,6000000,0

OK

at+pair 1 //Pairs with connection handle created when devices connected

OK

encrypt 1

PI:1, 0, 0, 5, 3

at+ldsc 1 //Disconnects the devices

OK

discon 1,22

ati 2009 //Confirms one device is stored in the bonding database

1

OK

at+bndt 01D1C4A981E5E7 //Confirms the BT_ADDR specified is bonded and stored in database

1,1,01D1C4A981E5E7

OK

atd 01D1C4A981E5E7 //Connects in vSP Mode (encrypted)

ENCRYPT

CONNECT 0, 01D1C4A981E5E7,15000,6000000,0

Do I have to use hardware RTS/CTS handshake with the Ezurio BLE modules?

We advice to use RTS/CTS hardware handshake on all of our SmartBASIC modules. This will avoid UART buffer overflow and loss of data.

However, if e.g. no hardware handshake signals are available on your host system, you might want to try

- Using XON/XOFF software handshake instead.

- Use not handshake at all but lowering the baud rate significantly. This can prevent buffer overflow to a certain extend but actually depends on your particular application and whether other tasks active on the module would consume processing power.

Make sure to always use the latest SmartBASIC firmware version and check the SmartBASIC and module documentation.

If not using SmartBASIC but implementing an own application with nRF Connect SDK or Zephyr, you are free to not use hardware handshake and implement a proper protocol to avoid buffer overflow on application side.

What are the hardware design recommendations for the BL653/BL654 USB interface if not used?

The BL653/BL654 provides an USB 2.0 full-speed (12 Mbps) interface which is compliant to the Universal Serial Bus Specification Revision 2.0. We recommend connecting VBUS to GND and leaving both D+ and D- data pins unconnected if developers do not need or want to implement the USB interface in their hardware designs. Please note that smartBASIC does not support USB functionality, so for software and application development you would need to either use Zephyr or the Nordic SDK.

Why does my BLE module have an extra 01 in front of its MAC address?

For example in SmartBasic Interactive mode

ati 4

10 4 01 EFA44957769F

00

BLE devices can have multiple mac addresses and if the mac address begins 01 as above it signifies it is a random static address which is assigned during manufacture. While its random nature means its not unique the number of possible random static addresses is 2^(48-2)-2 a very large number so it is very unlikely you will ever see a duplicate, let alone in the same place at the same time.

Other MAC address types include

- 00 IEEE assigned public address, the same as used by BT classic devices

- 01 Random static, generated at manufacture

- 02 Random private resolvable with IRK. resolvable by other devices already known

- 03 Random private non resolvable

To address privacy concerns, there are four types of Bluetooth addresses in a BLE device which can change as often as required. For example, an iPhone regularly changes its BLE Bluetooth address and it always exposes only its resolvable random address. This feature is known as LE privacy. It allows the Bluetooth address within advertising packets to be replaced with a random value that can change at different time intervals. Malicious devices are not able to track your device as it actually looks like a series of different devices. To manage this, the usual six-octet Bluetooth address is qualified on-air by a single bit which qualifies the Bluetooth address as public or random: ▪ Public – The format is as defined by the IEEE organisation. ▪ Random – The format can be up to three types and this qualification is done using the upper two bits of the most significant byte of the random Bluetooth address.

On Ezurio SmartBasic module, the address type can be set using the function BleSetAddressTypeEx(). On the other hand, Sysinfo$(4) can be used to retrieve the Bluetooth address if it is public or random static. Due to LE privacy 1.2, if the address type is random resolvable or random non-resolvable, it cannot be retrieved by the application layer since it is fully controlled by the baseband layer.

Note: The Bluetooth address portion in smartBASIC is always in big endian format. If you sniff on-air packets, the same six packets appear in little endian format, hence reverse order – and you do not see seven bytes, but a bit in the packet somewhere which specifies it to be public or random.

Does Ezurio support Nordic Enhanced Shock Burst (ESB)?

Yes, but software support should be sought direct from the Nordic Devzone as from Lairds point of view we provide only the hardware not the protocol.

Enhanced Shockburst (ESB) is a proprietary simple packet protocol for use in the Nordic modules. It is simple and easy to use and can give very low latency applications compared to BLE.

However, there is no encryption employed in ESB and ESB operates on a single frequency channel so there is no frequency immunity. You can implement your own encryption in upper layers though.

Also see Gazell (GZLL), which is another proprietary protocol from Nordic that builds on ESB.

Can I stop the BL65x firmware upgrade batch file from closing?

Smartbasic firmware is normally flashed to a BL65x module using a Windows batch file but the batch file command window will automatically close on completion. To keep this window open, to view what has happened add the following to the end of the batch file in question.

cmd /k

example below

.

.

.

:pauseend

if "%1" == "nopause" goto :end

pause

:end

cmd /k

Should I use nRFConnect SDK or nRF5 SDK with the Ezurio BL65x modules?

Nordic nRFConnect SDK, also known as NCS is based on the Zephyr RTOS with support for Laird modules based on nRF52 and nRF53

Nordic nRF5 SDK is a legacy bare metal SDK with support for Laird modules based on nRF51 and nRF52

You can choose either SDK but need to know that nRF5 SDK will not be supporting new features going forward. So if starting a new BL65x or BL5340 project then it is recomended to choose nRFConnect SDK.

See nRF Connect SDK and nRF5 SDK statement - Blogs - Nordic Blog - Nordic DevZone (nordicsemi.com) for more details

Do you support Bluetooth features like BLE Mesh, AoA (Angle of Arrival) and/or Angle of Departure (AoD) in your own AT Command Set Interface implementation?

No. There is no software support for BLE Mesh, AoA (Angle of Arrival) and Angle of Departure (AoD) in our current AT Command Set Interface implementation. Please feel free to build and develop your own BLE Mesh, AoA or AoD application in C by using the Bluetooth SDK and tools from Silicon Labs. In this case, as a starting point, we highly recommend the Simplicity Studio 5 IDE which offers a rich set / collection of example projects and templates.

Bluetooth Mesh is a wireless mesh topology and standard which enables many-to-many (m:m) device communication for an enormous number of local BLE devices. It supports large-scale node networks without the need of an ordinary BLE gateway infrastructure. Refer to https://www.ezurio.com/making-bluetooth-mesh-simple and https://www.bluetooth.com/learn-about-bluetooth/recent-enhancements/mesh for additional information.

Angle of Arrival (AoA) and Angle of Departure (AoD) are two concepts for location positioning and direction finding. Without going into too much detail and to keep things very simple: One of the two BLE devices must have at least two antennas or more, so that the data received from those antennas then can be used to identify the direction and angular position of the location where the Bluetooth signals come from. Please find further information available at https://www.ezurio.com/resources/blog/magic-bluetooth-aoaaod-direction-finding and https://www.bluetooth.com/blog/new-aoa-aod-bluetooth-capabilities.

Is it possible to clear or reset a table in smartBASIC?

Tables provide associative array (or in other words lookup type) functionality within smartBASIC programs. They are typically used to allow lookup features to be implemented efficiently so that, for example, parsers can be implemented.

There does not exist a function to delete particular entries from a table, but it's possible to overwrite existing elements with TableAdd(). TableLookup() will then return the new element. However, the elements are not actually being overwritten, but marked deleted and added newly to the table, hence the table memory consumption will increase.

To fully clear a table it's possible to simply call TableInit() again.

Can I read a file in SmartBASIC Interactive Mode with an AT Command?

While it's possible to open/write/close files from SmartBASIC Interactive Mode (AT+FOW, FWR, FCL) to e.g., enter configuration information for a SmartBASIC application, there is no AT command available to display the content of a file from the flash file system.

A workaround would be adding another SmartBASIC application to a device which can be started in Interactive Mode (AT+RUN or just the name) and opens the (config) file and prints the content to the console. Below is an example application.

Does the BL65x or BL5340 support Matter?

Matter can be supported on the BL5340 (nRF52840) and the BL654 when using the Nordic nRF Connect SDK. However, due to the memory requirements of Matter it can not be used on the BL653, BL652 nor the BL651 given their flash and RAM memory footprint.The BL653 (nRF52833) has 512K of Flash and 128K of RAM and BL652 and BL651 has less than that.

There are instructions on how to reduce the memory footprint for Matter in the documentation on the nRF Connect SDK Main branch, Memory footprint optimization » Matter, but even using this you will not be able to get it down to a size fitting on the nRF52833. With the steps from the optimization page with the light bulb sample the size was reduced to approximately 730 kB of flash and 170 kB of RAM when building for nRF52840, which is still way too high for the nRF52833. Additionally, there are possibilities that the Matter flash usage will grow more before the official release, as more bug fixes and things from the Matter specification will be added.

Why can’t I Re-open the UART when it closes when running AT Interface LPUART App?

The LPUART AT Interface app allows users to close down the UART port when entering low power Doze mode for additional power savings. The UART when it is open can consume as much as 350uA. The AT Interface LPUART app provides a cross-compile switch that allows the UART to close most of the time when there is no activity and the Tx/Rx buffers are empty. A “Keep UART Open” is implemented by using a GPIO that when low allows the UART to close after a low power operation timer has expired. When this Keep UART Open GPIO signal is high the UART will not close automatically.

The AT Interface Application sets the default GPIO used for this function to SIO_24. An application can chose any pin other than the default by writing the desired SIO port number to Sreg 109.

The BL65x EVK connects SIO_24 to Button 3. However, if running the AT Interface LPUART application on the EVK the UART will close automatically as soon as the low power timer expires (default set to 5 seconds). The UART can not be re-opened in the case. To reduce power the application configures the Keep UART Open GPIO to input pulldown. However, to operate properly Button 3 when pressed will pull the signal to ground which results in an Event interrupt. Since the GPIO uses an input pulldown it is already low and no Event occurs leaving the UART closed.

A simple change in $LIB$.AT.interface can be made to configure Keep UART Open GPIO to input pullup. This keeps the GPIO high at all times and the UART open. When Button 3 is pressed long enough for the low power time to expire the UART is closed. To re-open the UART Button 3 is pressed again which causes an Event which will re-open the UART.

Change the following line in InitGpio() function in $LIB$.AT.interface:

From:

rc = GpioSetFunc(vspCmdModePin, SIOTYPE_DIN, INPUT_PULL_DOWN)

To:

rc = GpioSetFunc(vspCmdModePin, SIOTYPE_DIN, INPUT_PULL_UP)

Also to change the functionality so once the UART is closed is remains closed until the next button press also change the next line in InitGpio().

From:

rc = GpioAssignEvent(0, vspCmdModePin, 0)

To:

rc = GpioAssignEvent(0, vspCmdModePin, 1)

How to avoid/disable module reset on UART break with SmartBASIC?

The default behaviour of the SmartBASIC driven BLE modules is entering deep sleep mode when a UART break condition is being detected and wake up through reset when released. While this is a convenient way to reset a module without having access to the reset line e.g., during development when connected with UwTerminalX, it might be unintended in the final application environment.

For the more recent SmartBASIC BLE modules like BL652, BL653, BL654, BL654PA the behaviour when detecting a UART break is configurable when opening the UART with UartOpen(). Character 9 in the stOptions string specifies the behaviour and it's possible to chose from entering deep sleep / reset, ignore the break or send an event EVUARTBREAK to the SmartBASIC application. See below table:

The default behaviour is entering deep sleep, hence you would have to close the uart and re-open it at the beginning of your application to apply changes to the behaviour.

See the SmartBASIC Extensions User Guides for each module for more details.

The BT900 dual-mode BT/BLE module does not offer configurability of the UART break behaviour and will always go to deep sleep and wake up through a reset.

How can I read out the MAC address from a BLE module during test/production?

A fast and convenient way to read out the MAC address of each module during a test/production process would be through SWD from FICR (Factory information configuration registers) registers DEVICEADDR[0] and DEVICEADDR[1]. The following command will read the MAC address from our BLE modules:

nrfjprog --memrd 0x100000A4 --w 8 --n 6

Please note that reading the MAC address with nrfjprog will give the raw register content whilst using the SmartBASIC command ATI 4 (or by using sd_ble_gap_address_get() from nRF SDK) will automatically set the highest two bits to '11', since this is a requirement by the BT specification!

Please also note that reading from memory through SWD will halt the CPU. If you need your application firmware to start afterwards (like for performing some test sequence) you would have to run the CPU with

nrfjprog –run

More information on FICR registers are available in the respective data sheets, like this for nRF52840 / BL654.

Do I still have to list/qualify my product with the BT SIG even if I don't use the BT logo?

Yes, you need to qualify/list any product that uses BT SIG intellectual property, even if you do not use the logo or require interoperability with other BT devices. see here for more details. Qualify Your Product | Bluetooth® Technology Website

How can a enable/disable particular BLE channels used for advertising/scanning or when in a connection?

The smartBASIC language provides functions for setting a specific set of channels to be used for BLE advertising/scanning or a BLE connection.

- BleChannelMap(chanMap$) enables or disables data channel usage when in a connection.

- BleAdvSetCreate(nSetId, nAdvProperties, nPriSecPhy, nFilterPolicy, peerAddr$, chanMask$) can set BLE advert channels.

- BleScanStartEx(scanTimeoutMs, nPriPhyScan, chanMask$, nFilterHandle) can set channels used for BLE scanning.

The channel map/mask has to be entered as a 5 byte long string for each of the functions and due to the little-endian architecture of the underlying ARM core its composition can be confusing. The below example will show the actual assignment of channel within that string. Furthermore the meaning of a set bit differs among the above functions.

- BleChannelMap() -> a set bit means channel is enabled!

- BleAdvSetCreate() and BleScanStartEx() -> a set bit means channel is disabled!

Now let's “visualize” the channel mapping into the five byte string:

channel number:

00000000|11111100|22221111|33222222|xxx33333 76543210|54321098|32109876|10987654|xxx65432 \byte 0/ \byte 1/ \byte 2/ \byte 3/ \byte 4/

So for enabling e.g., channels 9+10 only you would set the yellow bits:

00000000|11111100|22221111|33222222|xxx33333 76543210|54321098|32109876|10987654|xxx65432 \byte 0/ \byte 1/ \byte 2/ \byte 3/ \byte 4/ 0x00 0x06 0x00 0x00 0x00

giving “0006000000” as string.

For disabling channel only 35, i.e. active channels are 0-34 and 36, it would be:

00000000|11111100|22221111|33222222|xxx33333 76543210|54321098|32109876|10987654|xxx65432 \byte 0/ \byte 1/ \byte 2/ \byte 3/ \byte 4/ 0xFF 0xFF 0xFF 0xFF 0x17

giving “FFFFFFFF17” as string.

Further detail is given in the smartBASIC Extension Guides in the documentation section of the product page for each BLE module at Bluetooth Module Portfolio.

Does Ezurio have example code for a Windows Demo App which enables scanning and connecting to Bluetooth Low Energy peripheral IoT devices?

Unfortunately, we do not have an example of a Windows Bluetooth Low Energy application. If you require assistance with developing a Windows Bluetooth Low Energy application please contact one of our Sales Experts and let them know you are interested in a Design Services engagement and we will be happy to discuss your application requirements and provide a quote.

What factors influence the actual TX rate of the controller?

The actual TX rate is influenced by the PDU and MTU sizes along with the Connection Intervals and Slave Latency.

Where can I find the appropriate arguments/parameters to use with the BleAttrMetadata() function used in many examples in the BL65x User Guide, as I only see BleAttrMetadataEx() listed which appears to have different arguments/parameters?

The BLEATTRMETADATA () function is intentionally not documented in the BL65x Extension User Guides for our BL65x series smartBASIC modules, as it is preferred that the ‘EX’ variant BLEATTRMETADATAEX () is used going forward. The two functions are primarily the same, however, the EX version enables more functionality with the nFlags argument as compared to the FlsVariableLen argument in the deprecated BLEATTRMETADATA () function. The non-EX version is still supported to ensure old apps using it still work, including the code examples referred to in the user guide.

If you are looking for specifics about the BLEATTRMETADATA () function, such as the arguments and returns specific to that function these can still be found in the BT900 smartBASIC Extensions User Guide (pg 228), or BL600 smartBASIC Extensions User Guide (pg 110).

Can Pullups or Pulldowns be Disabled on Default UART Pins

The BL65x is delivered with the smartBASIC runtime FW loaded and no smartBASIC application. In this configuration the module will boot into smartBASIC Interactive mode and the default pins for the UART at startup are set as per:

- RTS: digital out, no pull, default high

- TXD: digital out, no pull, default high

- CTS: digital in, pull down

- RXD: digital in, pull up

Startup flow is as follows:

- sB engine starts

- If there is no autorun application - UART is opened (default parameters)

- If there is an autorun application - UART is not opened

- If the autorun application uses print - UART is opened (default parameters)

- If the autorun application uses UARTOPEN - UART is opened (custom parameters)

The pull up/down options can be changed in the smartBASIC application only when the UART is not open. If the $autorun application has opened the UART by using a print statement or calling UARTOPEN() then the UART must first be closed by calling the UARTCLOSE() function.

In the smartBASIC application when the UART port has been closed the code can call GpioSetFunc() to configure the desired GPIO parameters.

The smartBASIC application can use UARTOPEN() function to now enable the UART port. UARTOPEN() does not configure GPIO pull up/down configurations keeping the desired GPIO configurations intact.

How Can I Change the BL65x Tx Power Setting

The BL65x is delivered with the smartBASIC runtime FW loaded and no smartBASIC application. The BL65x will boot up in interactive mode and can be configured via AT Commands. In this mode the TX Power for both advertisements and connections is controlled via Config Register 109. This register is read from or written to via the AT+CFG AT command as is described in the BL654 smartBASIC Extensions Users Guide. However, Config register 109 is valid for Tx Power adjustment when Virtual Serial Port services is enabled.

If Virtual Serial Port Services is not enabled TX Power is configured via the BleTxPowerSet() function within a users smartBASIC application code. In this mode the current setting of Tx Power can be obtained from ATI register 2008 as described in the BL654 smartBASIC Extensions Users Guide

How many SPI Interfaces does the BL65x support

The BL654 Data sheet lists four SPI Interfaces (up to 8 Mbps) are supported. The data sheet is provided as a hardware guide and refers to the hardware itself. The Nordic nRF52840 MCU supports up to 4 SPI instances. However, the actual number of SPI interfaces depends on what SW is used for application development. If using smartBASIC for development there is one SPI instance that can be configured as SPI master.

The SPI port is opened via smartBASIC function SPIOPEN(). This function includes parameters that allow configuration of SPI Mode, SPI Clock Rate and SPI Flags. SPI pins cannot be configured and use the pins that are specified in the BL65x Data Sheet. Refer to smartBASIC Core Functionality Specification. SPI_CS is not controlled in smartBASIC firmware and must be controlled by the application through use of SIO pins.

For applications developed using Nordic SDK or Nordic Zephyr SDK the nRF528xx MCU supports up to 4 SPI Instances. There can be up to 4 SPI Master interfaces (SPIM Master) and up to 3 SPI Slave interfaces (SPIS) but not all at once. There are four total SPI interfaces and master/slave combinations are shared across those four instances. The nRF528xx also contains two I2C Instances which are shared with the two lower SPI instances via TWI. Refer to the latest nRF52xx data sheet for details.

How many I2C ports does the BL65x support

The BL65x Data sheet lists two I2C controllers (up to 400 Kbps) are supported. The data sheet is provided as a hardware guide and refers to the hardware itself. The Nordic nRF528xx BLE mcu’s support multiple I2C controllers. However, the actual number of I2C interfaces depends on what SW is used for application development. If using smartBASIC for development there is one I2C instance and that instance is a master, there is no slave support.

Referring to the smartBASIC Extensions guide for the various BL65x modules it states:

Note I2COpenEx() allows for SCL and SDA to be routed to other GPIO pins.

This function uses the same I2C instance but allows changing the pins it is operating on. The smartBASIC I2C driver does not support a second instance. The intent of this function is so multiple devices with the same I2C address can be used. Some devices support a single address, some have multiple addresses they can use. If a sensor with 2 possible addresses is used then a third cannot be added on the same bus because the address of 2 devices will clash, but it can be used on different pins. Another example is if one sensor only supports 100KHz mode but another that supports 250KHz. Different busses would need to be used so that the 250KHz signals do not cause undefined operation for the 100KHz sensor

For applications developed using Nordic SDK or Nordic Zephyr SDK then I2C interfaces supported by the particular nRF528xx BLE MCU can be used. Both master and/or slave operation is also supported. Refer to the nRF828xx data sheet for details.

Why is the data I am sending in an advertisement PDU seem to be received as converted ASCII data?

When sending extended or normal advertisements by setting AD Elements for scan or advertise response PDU’s using AT+AARA tag,<payload> or At+ASRA tag, <payload> the parser is expecting the payload to be a string enclosed by quotes.

However, how do you differentiate between a normal text string and a string of ASCII hex?

Is FF 0x46 0x46

Or is it

0xFF.

For example if the data added in the response packet is:

T+AARA tag, “BEEF”

The parser interprets this as a four byte string of 0x42, 0x45, 0x45, 0x46

If the command is changed to:

At+AARA tag, “\BE\EF” the parser would interpret this as a two byte string of 0xBE, 0xEF. The slash interprets the following two characters as ONE hex byte.

How many bytes can BL65x modules support for Extended Advertising using smartBASIC?

BL65x modules can support up to 255 Bytes when using extended advertising. This equates to an advertisement packet being sent on one secondary channel.

Extended Advertisement were introduced in Bluetooth SIG v5.0 specification. Advertisement channels 37, 38 and 39 are now qualified as Primary Advertisement Channels with channels 0 to 36 now qualified for use as Secondary Advertisement Channels. Each secondary channel can have up to 255 bytes of payload and the v5.0 specification allows for chaining up to 6 packets for up to 1650 bytes total. However, receiving all of those chained packets may be unreliable resulting in many stack vendors not offering the full chaining capacity.

How can I update and send Extended or Normal Advertisement data using AT Interface application?

In AT Interface there are just a few commands for modifying and sending Extended or Normal Advertisement data. Extended Advertisement Data is provided from the Server to the Scanner via Scan Request and Response PDU’s. An AD Element needs to be created to add the AD report that is returned after a scan request is received. To add AD Elements to the Advert Report use AT Command:

AT+AARA tag,”payload”

Tag refers to the Data Type Value specified in the Bluetooth SIG Generic Access Profile document. Using a tag of Data Type Value of 0xFF <Manufacturing Specific Data> the command will look like:

AT+AARA 0xFF “payload”

Or

AT+AARA 255 “payload”

Once the AD Report is updated it must be committed using:

AT+ACMT

To begin Extended Advertisements use AT Command:

AT+EADV <advProp>,<advIntvlMs>,<maxCount>,<priSecPhy>,<peerAddr>, <chanMask>

Refer to AT Interface Guide for more details of parameters.

For now the key parameter is <advProp>. <advProp> is a bitmask where bit 0 is set for connectable adverts, bit 1 is set for scannable adverts, bit 2 for directed adverts and in that case ‘peerAddr’ must be a valid 14 hex digit string and bit 3 is set for extended adverts. For this example AT Command:

AT+EADV 8

This command will begin sending non-connectable Extended Advertisements using default values for remaining fields which are taken from their corresponding S Registers.

To clear AD Elements when new advertisement data needs to be sent use AT Commands:

AT+ARST 1

followed by

AT+ARST 0.

This will clear existing AD Elements. If the need to maintain current AD Elements for the Advert report but additional AD Elements need to be added to the Advert Report then simply continue adding AD Elements using

AT+AARA

and

AT+ACMT

commands.

What influence does the client have when it comes to notifications?

The Client must initiate the ability of the Server to send Notifications by writing to the CCCD descriptor for the Notified Characteristic on the Server.

Why are multiple EMPTY_PDU are being sent from the Master per connection interval?

The communications protocol for Bluetooth is a ping pong type style, so every connection event begins with the Master sending the slave a packet and the Slave then responds to that packet with any data it may have. Therefore, when the Master has no data to transmit it will send an EMPTY_PDU to the Server and the Server, if it has data to send, will send back the data in response. You can see this readily where there is no data transmissions, the Master and Slave ping pong EMPTY_PDU’s back and forth on every connection event, if Slave Latency was incorporated then during these periods of no data transmissions you would see Master send EMPTY_PDU and no response from Slave because it has no data to send and was allowed to skip the connection event because of it.

Error received when flashing custom Nordic application to DVK-BL65x: SVCALL(SD_SOFTDEVICE_ENABLE, uint32_t, sd_softdevice_enable(nrf_clock_lf_cfg_t const * p_clock_lf_cfg, nrf_fault_handler_t fault_handler)); Programming custom Nordic App to DVK-BL65x

This error indicates and issue with the clock source referenced in your code. We recommend referencing the appropriate Application Note for Using the DVK-BL65x and Nordic SDK linked below:

- Application Note - Using the DVK-BL652 and Nordic SDK

- Application Note - Using the DVK-BL653 and Nordic SDK

- Application Note - Using the DVK-BL654 and Nordic SDK

As noted in the Application Note, by default the DVK-BL65x uses the on-chip RC oscillator as its clock source, as opposed to Nordic's development kit or dongle which use an external crystal. The difference in oscillator source should therefore be reflected in the SDK as shown Application Note. Alternatively, you can connect an external crystal as per BL65x DVK User Guide

Can the BL5340 or BL65x use a different stack to support a hosted application?

Theoretically as long as whoever 3rd party BLE stack is used is tested and supported on Nordic nRF5340 or nRF528xx used on BL65x modules.

Laird would not have tested anything other than Zepher/nRF SDK.

A 3rd party CODEC could be used as well as long as it is targeted for nRF5340. However, licensing would need to be considered.

What is the maximum number of characteristics that can be supported using smartBASIC?

The maximum number of characteristics is not a limitation in smartBASIC but a limitation in the underlying Nordic SoftDevice SDK. The SoftDevice has a maximum RAM allowance of 64KB, adding more characteristics will increase RAM usage and depending on other configuration, will determine how many characteristics can be supported within the 64KB allowed RAM space.

The maximum number of characteristics supported in smartBASIC is roughly 24. This is a product of the combination of the total RAM allowance of 64K for SoftDevice, GATT Table configuration as well as the GATT Table size as is specified in Configuration Key 204 (refer to BL654 smartBASIC Extension Guide). The default GATT table size is 1792 bytes (Config 204)) which will allow for roughly 11 characteristics.

If using the AT Interface application the maximum number of characteristics is set to 24 by default. The default configuration can be found in $autorun$.AT.interface.BL654._.sb file:

//This defines the maximum number of characteristics we can manage

#define MAX_CHARACTERISTICS 24

As mentioned previously this is the max number of characteristics that can be supported but Out of Box the GATT table size is 1792 bytes resulting in roughly 11 characteristics.

How to open multiple BLE connection simultaneously with the SmartBASIC AT interface?

While it is not possible to open multiple virtual serial port (VSP) connection at a time, it is possible to open more than one regular BLE connection.

The SmartBASIC AT interface application provides configuration S registers for setting certain BLE parameters, which are accessible by the ATS command. The default configuration is optimized for establishing one VSP connection with high throughput between two BLE modules. Given this, certain S register have to be modified to accomodate for different applications.

The default configuration has set bit 3 in S register 100 (Start-up Flags), which gives max bidirectional throughput of about 127kbps. As a consequence the number of simultaneous BLE connections is being limited to 1. If you want to use more than one non-VSP BLE connections, bit 3 in S register 100 needs to be cleared and then max connections in S register 126 can be increased.

- ATS 100=1 (if you want to keep the VSP service being active)

- ATS 100=0 (if you want to disable the VSP service)

If you need to set other bits in S register 100, like data length extension or phy rate, add them as required. You can use ATS 100? to retrieve the current settings before changing.

Now the number of simultaneous BLE connections can be set in S register 126.

- ATS 126=8 (set max connections to eight or some other value, the actual maximum number might depend on your particular BLE module)

Then make sure to save and apply the new settings.

- AT&W (this will store S register settings permanently)

- ATZ (does a soft reset and apply changed settings of S registers)

After the soft reset the new settings are active and you can open several BLE connections simultaneously with AT+LCON command.

See BL65x AT Interface User Guide for more information on S register settings and AT commands.

Is achieving the theoretical throughput of 2 Mbps possible with BLE radio with 2M PHY?

Unfortunately, no. At the time of this writing, even with 2M PHY enabled, BLE 5.x radios have a limitation of 1.2 - 1.5 Mbps due to the packet format. In order to achieve throughput of 2Mbps or higher you would have to use a different RF Technology, such as Wi-Fi.

Please see the Application Note for Throughput Testing with Bluetooth 5 LE 2M PHY Feature for the BL65x module.

- Throughput Testing with BT 5 - LE 2M PHY Feature v1 0.pdf

- Throughput Testing with Bluetooth 5 - LE 2M PHY Feature - BL652.pdf

(Note: The above Application Notes have not yet been added to the BL653 or BL654PA Product Pages, however, they do apply to those modules as well. The only difference is the DVK setup.)

Is it possible to have multiple connections as a peripheral device on the BL65x modules?

Multiple connections as a peripheral device is currently not supported in smartBASIC on the BL65x modules. This functionality is supported in Nordic SDK beginning with SoftDevice S132 v.4.0.0.

However, as of the writing of this FAQ, this functionality has been brought out as an experimental feature in the smartBASIC firmware for the BL654/BL654PA only, as per the Release Notes for the v29.5.7.2.0 fw It is not documented in the smartBASIC Extensions User Guide at this time due to it being an experimental feature, and no additional support is currently available for this functionality.

If interested in testing with this experimental feature, the below test can be performed using two/three mobile devices (tablets/phones) as the central devices to demonstrate that two (or more) central role devices can connect to the BL654 configured as a peripheral at the same time. (This does not test GATT functionality or anything else.) While in interactive command mode:

at+cfg 205? // Query the current MAX number of peripheral role connections (User Guide still indicates the MAX this can be set to is 1)

at+cfg 206? // Query the current MAX number of central role connections

27 0x00000001 (1) //Response to MAX Peripheral role connections

00

27 0x0000000F (15) //Response to MAX Central role connections

00

Increase the MAX Peripheral role connections and decrease the MAX Peripheral role connections and then reset the module for the settings to take effect:

at+cfg 205 3 //Configure Max Peripheral to 3

at+cfg 206 3 //Configure Max Central to 3

atz //Reset

In our testing we used the cmd.manager.sb sample application available from the BL654 Sample Application Repository on GitHub. After setting the MAX connection parameters and resetting the device load and run the cmd.manager.sb sample application.

The commands and parameters for cmd.manager are found in the comments section of the code: To simplify this for testing purposes enter the following command to start adverts:

advert undirected 250 30000 0

Explanation of the command from the code:

advert undirected #INTintervalms# #INTtimeoutms# #INTfilterpolicy#

// - Use this to start adverts of type ADV_IND using the parameters specified

// - #INTfilterpolicy# is 0=no filtering, otherwise set 1 to 4 which is the

// - whitelist handle created using the 'whitelist' command

This will start adverts for 30 seconds, adjust the INTtimeoutms setting if you want to advertise for longer. Then while it is advertising, connect to it using your phones/tablets (central role devices). If the advert times out before you connect the additional devices you can restart it with the advert

undirected 250 30000 0 command.

Is there a way to extend the shelf life of Ezurio modules?? If the shelf life cannot be extended in any way, what are the consequences of using modules after shelf life?

The shelf life statements are essentially to prevent mishandling of the product and not storing it properly. If the modules are still sealed in the package, stored at the proper temperature and have not been exposed to moisture they should be fine. However, when working with modules beyond their shelf life you MUST bake the modules before populating the them to your board. Failure to bake the modules could result in the yield rate dropping down lower than expectation due to popcorn or de-lamination on the modules. It is recommended that you follow IPC/JEDEC J-STD-033 which is the general standard for the handling, packing, shipping and use of moisture/reflow sensitive surface mount devices.

Our main concern is around the castellation/pads which solder the module to the board. It is imperative those pads do not get tarnished, as this would cause soldering issues. Humidity can affect solderability as well, as if there is any excess moisture in the solder on the module, during reflow of the module to the board, steam balls can essentially explode the solder and sometimes result in an open circuit (or possibly a short circuit).

As long as all of the moisture handling and temperature guidelines are being followed you will likely have no issues. It is further recommended that when you do the build with modules that have exceeded their shelf life that you start with a handful to perform a test run and do a final test to make sure all is working as expected. As long as there are no issues with the initial test run we would expect that you will not experience any problems.

What does the Bluetooth message "advertised data length corrected" indicate?

This is effectively a Bluetooth SPAM message. It indicates the advert data being parsed is less than a full advert record can be, in other words trailing zeroes were removed.

How do I select the 32.768kHz Low Power Clock Source in the new nRF Connect SDK

Customers using the new nRF Connect SDK from Nordic will need to change the low power 32kHz clock source when working with the BL65x family of products.

To do this in the new SDK using the Segger IDE follow the instructions here;

- In Segger Embedded Studio select Project --> Configure nRF Connect SDK Project

- Filter the list for 'osc' or drill down in the list to the Device Drivers --> Hardware clock controller support --> NRF Clock controller support --> 32KHz clock source

- Select the clock source based on your configuration/design:

- Without the optional external 32khz xtal, default configuration for our modules, select 'RC Oscillator'

- With the external 32Khz xtal connected to the module, select 'Crystal Oscillator'

With the correct value selected your code should build with the right clock source configuration and your application should run smoothly.

Can I use Windows to scan for my BLE Peripheral and Connect to it?

Laird does not provide a Windows utility for scanning and connecting to BLE devices. We are also not aware of any existing third party apps to do this either. Android and iOS are the best options for scanning for and connecting to BLE radios.

Getting ERROR: JLinkARM DLL not found. Please reinstall latest JLinkARM when trying to flash BL65x module via the JTAG interface. How can this be resolved?

If you are getting ERROR: JLinkARM DLL not found. Please reinstall latest JLinkARM, you will need to download and install the updated Segger drivers for the J-Link.

Segger J-Link Drivers

What could be causing additional power draw when in standby doze state?

There are several functions within an application that can increase current consumption above the measurement indicated in the Datasheet for standby doze, low power mode.

- Timers

- GPIOs held in an asserted state

- LEDs

- Nested functions - which keep the module from entering the standby doze state

- UART (when open)

What are the production programming options for the BL65x modules when using smartBASIC?

For production programming we recommend the following options:

- FLASH cloning: Instructions for FLASH cloning can be found in the firmware Zip files, which can be downloaded from the BL65x Product Page. There are two README files contained in the "Firmware" folder of the files, as well as the utilities required to create the cloned image. The first option, ____READ_ME_TO_CLONE_FILESYSTEM___, captures only the flash file and data system and does not include the firmware. The second option, READ_ME_TO CLONE FIRMWARE_&_APP__, clones the flash file and data system as well as the firmware. When possible, we recommend cloning the firmware as well as the flash and data systems.

- MultideviceLoader, which is a command-line application for Windows, Linux and Mac that can be used to XCompile an application (Windows only) and download it to multiple Laird devices at the same time and provides options for: renaming the file, running it after download and other functions. This is a companion application for UwTerminalX and is mostly suited to production/end-stage testing purposes. Command line arguments are available in the Wiki on the GitHub repository.

Note: UwFlashx and Uwflash_embed are for firmware upgrades, and cannot be used to program smartBASIC applications.

How do I program BL65x modules in production or in the field (Tag-Connect)?

Consider using a PCB pad layout with support for Tag-Connect for JTAG which allows for easy, low cost programming in production or in the field.

Note: Laird recommends you use JTAG (2-wire interface) to handle future BL65x module firmware upgrades. You MUST wire out the JTAG (2-wire interface) on your host design , where four lines should be wired out, namely SWDIO, SWDCLK, GND and VCC. Firmware upgrades can still be performed over the BL65x UART interface, but this is slower (60 seconds using UART vs. 10 seconds when using JTAG) than using the BL65x JTAG (2-wire interface).

Is it possible to use Nordic's UART Serial Port Service when a BL65x module is configured for UART Bridge Mode rather than using Ezurio's Virtual Serial Port Service?

Yes, if config key 112 set to 1, via the AT+CFG 112 command then the service UUIDs for the UART serial port service is as per Nordic’s implementation. Any other value will use the service UUIDs for Laird’s custom service - vSP (Virtual Serial Port).

Please reference the Virtual Serial Port Service Managed section in the smartBASIC Extensions User Guide of the BL65x module you are working with for additional information.

Issues with Flashing custom firmware to BL65x using Segger Embedded Studios IDE

The BL652, BL653, and BL654 modules come preloaded with our smartBASIC firmware. When flashing custom firmware using Segger IDE it is necessary to do a full erase of the Laird BL65x module before programming the module. This can be accomplished using the NRFJPROG command line tool to send the command nrfjprog --eraseall.

How can I connect a Bluetooth Low Energy Device to a PC?

Bluetooth Low Energy uses Services as opposed to the set of standardized profiles that exists for Classic Bluetooth. While some Bluetooth Low Energy services have been standardized by the Bluetooth SIG, the development of custom services is allowed to meet custom application requirements.

Because Bluetooth Low Energy uses a completely different protocol than Classic Bluetooth and supports custom services, Bluetooth Low Energy devices cannot connect to a computer through the typical Bluetooth configuration of a computer. Therefore, connecting to a PC requires writing and running a Bluetooth Low Energy Central Role/Client application to collect the data sent from the Bluetooth Low Energy peripheral modules. Application development for PCs and Mobile devices is outside the scope of our support. Alternatively, a BL654 USB dongle could be used as a BLE Central Role device, to collect the BLE data and pass it to the PC over a COM Port. However, you would still need an application to view and process the data received over that COM Port.

We generally recommend customers who are new to Bluetooth Low Energy obtain a copy of Getting Started with Bluetooth Low Energy to help them understand the Bluetooth Low Energy protocol and the GATT table. There are also many resources available online which explain this. For developers interested in exploring more advanced multi-protocol hardware options, the BL54L15 Series Bluetooth LE + 802.15.4 + NFC module provides a versatile, compact solution that could enhance your BLE setup while fitting naturally alongside the tools and concepts described here.